DTF transfers, or Direct-to-Film transfers, have revolutionized the landscape of custom printing, offering designers an innovative way to bring their ideas to life. This advanced DTF printing technology enables the creation of vibrant fabric designs with remarkable detail and clarity, making it an ideal choice for fashion enthusiasts and apparel businesses alike. Unlike traditional screen printing, DTF transfer techniques are incredibly versatile, allowing for prints on various materials such as cotton and polyester without the limitations usually faced by other methods. As we navigate this post, you’ll discover the secrets to mastering DTF transfers, from understanding the technology to employing tips that ensure your designs truly stand out. Dive in to explore how you can harness the power of DTF by creating stunning, high-quality graphics that elevate your apparel and showcase your unique style.

When exploring the world of fabric printing, one might encounter terms like Direct-to-Film transfer, film transfer printing, or even custom heat transfers. These artistic techniques focus on transferring eye-catching designs onto garments, providing a perfect blend of creativity and technology. Whether referred to as DTF printing or its alternatives, the core principle remains the same: achieving detailed and colorful designs that resonate with customers. In this discussion, we will delve into the innovative processes that facilitate exceptional print quality, using these techniques to enhance the appeal of any fashion line. Join us as we uncover the potential of these modern printing methods in transforming simple fabrics into captivating works of art.

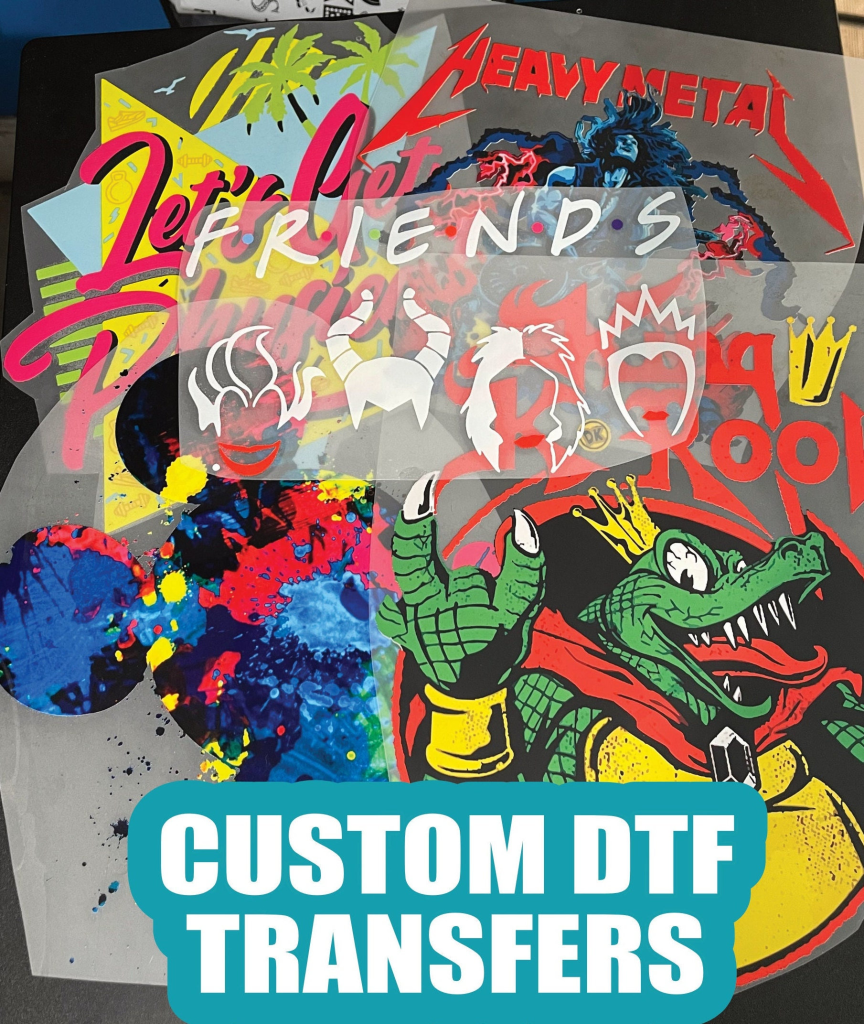

The Power of DTF Printing Technology

Direct-to-Film (DTF) printing technology transforms the custom apparel landscape by allowing designers to capture intricate details and vibrant colors directly onto a variety of fabrics. This method combines traditional printing artistry with modern technology, yielding stunning results that truly stand out. DTF printing uses specially formulated inks that adhere beautifully to the transfer film, maintaining their vibrancy even after washing, making them an ideal choice for long-lasting custom prints.

The flexible nature of DTF printing means that it can be applied on both light and dark fabrics without compromising on quality. As designers increasingly seek to innovate, DTF printing technology offers the capability to produce bold graphics that catch the eye. With its efficiency and versatility, DTF becomes not just a method but a dynamic tool for fabric design, revolutionizing how brands approach garment decoration.

Creating Custom DTF Prints

Creating custom DTF prints begins with a unique design, whether it’s for promotional merchandise or personalized fashion items. Designers can utilize graphic design software to manipulate images, ensuring clarity and vibrancy align with the brand’s vision. Once the design is crafted, it is printed onto a film that will later be transferred to fabric. This initial stage combines creativity with technical expertise to ensure the final product exceeds expectations.

To achieve remarkable custom prints, it’s essential to select the right materials for the process. High-quality transfer films and inks will dramatically impact the outcome and durability of the prints. Investing in premium DTF supplies allows designers to explore intricate designs and various textures, while ensuring that the final prints reflect the desired aesthetic. With DTF transfers, the possibilities for customization are nearly endless.

DTF Transfer Techniques for Quicker Production

One of the most significant advantages of DTF transfer techniques is their efficiency in production. Unlike traditional methods, DTF printing minimizes setup time, allowing businesses to quickly respond to market demands. This is particularly beneficial for small businesses and independent designers who may not have extensive resources but seek to deliver timely and custom apparel in competitive environments.

Moreover, DTF transfer techniques can easily adapt to different print runs, whether small batches or larger quantities. This flexibility ensures that production lines can maintain quality and consistency without the need for extensive alterations. Understanding how to implement these techniques effectively can greatly enhance design workflows and lead to increased customer satisfaction through swift delivery times.

Innovations in DTF Printing and Market Opportunities

The DTF printing market is rapidly expanding due to continuous innovations aimed at enhancing the user experience both for designers and consumers. New advancements in printing technology, such as improved ink formulas and more efficient heat presses, are driving demand for custom DTF transfers. Companies are now positioned to offer superior products while improving production timelines, opening up opportunities for creative entrepreneurs.

Furthermore, as businesses look to cater to diverse customer needs, the market for DTF printing is diversifying. Fortunate designers can leverage these advancements to attract a broader clientele, including enthusiasts looking for unique, custom pieces. Embracing the latest innovations allows businesses to elevate their offerings and solidify their position in a competitive market, ensuring sustainability and growth.

Essential Tools for DTF Printing Success

The success of DTF printing relies significantly on using the right tools and equipment. High-quality DTF printers, such as those designed by leading manufacturers, are essential for ensuring that the prints are vibrant and detailed. These printers allow for greater control over various settings, leading to optimal results in every print run.

Additionally, tools like heat press machines play a crucial role in the application of DTF transfers. Selecting the right type of heat press—whether clamshell, swing-away, or drawer-style—can impact the transfer quality. By investing in reliable tools and staying updated with the latest printing technology, designers can ensure their DTF prints are always of the highest standard.

Best Practices for Maintaining DTF Transfer Quality

Once you have achieved stunning designs using DTF transfers, maintaining their quality becomes essential for longevity. Washing care plays a crucial part in preserving the colors and integrity of the DTF prints. Designers should recommend specific washing instructions to customers, such as cold washing and avoiding harsh detergents, to extend the life of the garments.

Additionally, handling the prints with care during the application and storage process can prevent unwanted wear and tear. Preheating fabric and allowing proper cooling times after transfer can significantly enhance adhesion, preventing peeling or fading during washes. By sharing these best practices, designers can help ensure that their customers enjoy their vibrant prints for years to come.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a process where designs are printed onto a special film and then transferred to fabric using heat. This method allows for vibrant colors and intricate designs on various materials like cotton and polyester, offering versatility that many traditional printing methods lack.

What are the advantages of using DTF transfers over traditional printing methods?

DTF transfers offer several advantages including the ability to print on a wider range of fabrics, the use of the same inks for different materials, and fewer setup requirements. This results in quicker production times and lower costs, making DTF printing an appealing option for both small businesses and large manufacturers.

How can I create stunning designs with custom DTF prints?

To create stunning designs with custom DTF prints, ensure you use high-quality transfer materials and printers. Utilize design software to craft intricate graphics, preheat your fabric before application, and follow correct heat and pressure settings to achieve vibrant and durable prints.

What types of fabrics can DTF printing be applied to?

DTF printing is highly versatile and can be applied to a wide variety of fabrics, including cotton, polyester, and even blends. This flexibility allows designers to explore vibrant fabric designs across different apparel types.

What tips should I follow for effective DTF transfer application?

For effective DTF transfer application, be sure to preheat your fabric, use the appropriate temperature and pressure as per guidelines, allow the transfer to cool before peeling, and exercise care during washing. Following these tips will help ensure your DTF prints last and maintain their quality.

Where can I find reliable suppliers for DTF transfers?

To find reliable suppliers for DTF transfers, look for online platforms that specialize in custom DTF printing services. Consider reading reviews and requesting samples to assess quality. Engaging with online communities can also provide recommendations for the best sources for DTF transfers.

| Aspect | Details |

|---|---|

| Definition | Direct-to-Film (DTF) printing is a technique that prints designs onto a film, which is then transferred to fabric using heat. |

| Materials | DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blends. |

| Advantages | Vibrant colors, exceptional detail, soft finish, and versatility across different materials. |

| Comparison | Unlike traditional methods like screen printing, DTF printing is quicker, requires fewer setup steps, and has fewer limitations on material types. |

| Recent Innovations | The DTF market is expanding with new tools like the A3 DTF printer and custom DTF transfer services, enhancing user experience. |

| Tips for Use | 1. Preheat fabric. 2. Follow heat settings and pressure guidelines. 3. Allow cooling before peeling. 4. Wash garments correctly. |

Summary

DTF transfers are revolutionizing the world of garment design, opening up a wealth of possibilities for anyone involved in apparel printing. This innovative technique allows artists and designers to create stunning, vibrant designs with clarity and detail that exceeds many traditional methods. As the technology evolves, the tools available to artists also enhance the creative process, ensuring greater accessibility and high-quality results. For those keen on exploring custom apparel, understanding how to effectively leverage DTF transfers can transform your design capabilities and ignite your artistic potential.