DTF Transfers, or Direct-to-Film transfers, are revolutionizing the world of textile printing by providing unparalleled capabilities for transferring detailed and vibrant designs onto various fabrics. This innovative technology simplifies the process of creating custom apparel, catering to both businesses and crafting enthusiasts looking for high-quality results. The myriad advantages of DTF printing, including its versatility across materials and cost-effectiveness for short runs, make it an ideal choice in today’s competitive market. As the demand for personalized products grows, the ongoing advancements in DTF technology promise to reshape the landscape of textile printing. Embracing DTF solutions not only enhances production efficiency but also allows for creative expression in fabric design, setting a new standard in the industry.

Known alternatively as Direct-to-Film printing, DTF technology encompasses a sophisticated method that is changing the way designs are transferred onto fabric. This cutting-edge approach leverages specialized films and heat-pressing techniques, enabling high-resolution images to be applied easily and accurately. As brands and creators seek innovative methods for producing customized apparel, DTF printing emerges as a compelling option, distinguished by its efficiency and ability to handle intricate designs. The ongoing advancements in textile printing innovations further enhance the appeal of DTF solutions, making them increasingly popular among retailers and artists alike. With its unique blend of quality and cost-effectiveness, DTF continues to redefine the possibilities in the printing landscape.

Understanding the Basics of DTF Transfers

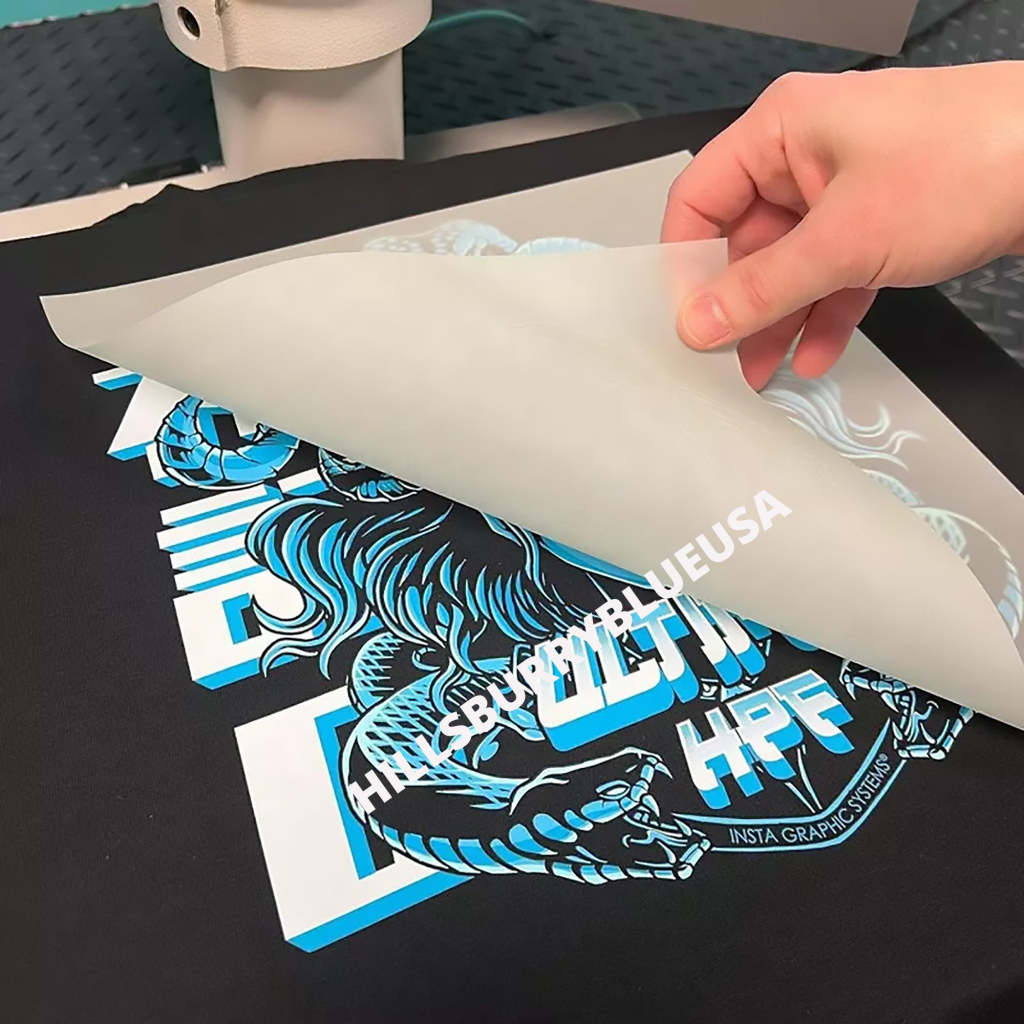

DTF transfers, or Direct-to-Film transfers, represent a revolutionary step in the textile printing world. This innovative technology allows for intricate designs to be printed onto a special film, which can then be applied to various fabric types using heat and pressure. The capacity of DTF printing to handle multiple materials—including cotton, polyester, and blends—makes it exceedingly versatile. By enabling high-resolution printing with vibrant colors and detailed graphics, DTF has become a preferred choice for custom apparel production. Whether for personal projects or larger commercial enterprises, DTF opens possibilities for unique, customized designs.

The DTF process is straightforward yet efficient, appealing to those who may be unfamiliar with traditional screen printing or Direct-to-Garment (DTG) methods. Unlike DTG, which relies heavily on the type of fabric and sometimes produces less vibrant results on darker materials, DTF transfers provide clarity and boldness regardless of fabric color. Furthermore, the technological advancements behind DTF ensure that the prints are durable, wash-resistant, and maintain their integrity over time, making it a reliable option for custom apparel.

Key Advantages of DTF Printing Technology

Among the standout benefits of DTF technology, versatility ranks highly. The ability to print on a wide array of fabrics means businesses can cater to diverse customer needs, whether it’s for t-shirts, bags, or home decor items. DTF transfers are not limited to cotton or specialty fabrics; they can seamlessly bond to polyester and its blends, thus appealing to a broader market segment. This flexibility not only enhances product offerings but also boosts profitability by enabling businesses to explore various textile applications.

Another significant advantage of DTF printing is its cost-effectiveness for short-run orders. Traditional textile printing methods often involve high setup costs and complexities, which can be prohibitive for small orders. In contrast, DTF technology allows for economical production, making it an attractive option for startups and small businesses that are entering the custom apparel market. By reducing the financial barrier to entry, DTF printing enables more entrepreneurs to express creativity and cater to personalized demands.

With an emphasis on high-quality output, DTF transfers excel in delivering intricate designs that can be a challenge for alternate techniques. The capacity to produce fine details and gradients attracts businesses looking to stand out in a competitive market where unique designs are paramount. This ensures that clients not only receive aesthetically pleasing products but also enjoy the longevity of high-quality prints that are resistant to fading and wear.

Recent Innovations in DTF Technology

Recent advancements in DTF technology have propelled its adoption into mainstream textile printing. Companies like Eazydtf are leading the charge by investing in high-capacity DTF printers that streamline production processes. By incorporating cutting-edge machinery capable of delivering rapid output while maintaining exceptional print quality, businesses can meet the heightened demand for custom designs without compromising on turnaround times. Such innovations not only enhance customer satisfaction but also allow businesses to stay competitive in a fast-paced market.

Additionally, platforms like Snuggle DTF have emerged to simplify web-to-print operations, facilitating smoother transactions for businesses looking to harness the capabilities of DTF printing. These integrated solutions enable users to upload their designs conveniently and manage their printing projects seamlessly. As the textile printing industry evolves into a more digital-driven sphere, technological solutions will play a crucial role in bridging the gap between design and production.

The Role of Education in DTF Printing

As DTF technology continues to evolve, educational initiatives are essential for businesses and individuals looking to leverage its benefits. The GJS company’s upcoming webinar titled ‘Discovering DTF’ aims to enlighten participants about the latest advancements and practical applications of DTF printing. With real-world demonstrations showcasing innovative printers capable of producing 500 garments per hour, attendees can gain valuable insights into boosting their production efficiency and exploring new creative possibilities. Such educational platforms encourage community engagement and networking, fostering a collaborative spirit among industry professionals.

Understanding the mechanics of DTF printing also empowers users to maximize their investment in technology. By acquiring knowledge about various printer settings, transfer materials, and design preparation techniques, businesses can enhance output quality and reduce Waste. As DTF technology becomes increasingly accessible, continuous learning will enable printers to adapt and innovate, keeping pace with industry trends and consumer demands.

Comparative Insights: DTF vs. Sublimation

In the ongoing discussion surrounding textile printing methods, DTF and sublimation are frequently compared. While sublimation printing works best with polyester fabrics and requires specific conditions for optimal results, DTF technology emerges as a more versatile solution. One of DTF’s greatest attributes is its ability to cater to a wider variety of materials; businesses can produce prints on cotton, blends, and many other textile types, which sublimation cannot achieve. This breadth of application positions DTF as a more adaptable option for enterprises looking to diversify their product lines.

Furthermore, DTF printing proves advantageous when managing smaller batches, negating the need for extensive setup processes associated with sublimation. As manufacturers aim to meet the rising demand for personalized apparel, understanding these comparative insights becomes essential for making informed choices in production strategy. By recognizing the inherent benefits of DTF over sublimation, businesses can position themselves strategically in the custom apparel market.

The Bright Future of DTF Technology

As the textile printing industry continues to embrace innovations, the future of DTF technology looks promising. Companies worldwide are ramping up investments to enhance their DTF capabilities, indicating a strong belief in the technology’s potential to dominate custom apparel production. With ongoing advancements in printing technology and techniques, DTF is set to redefine the standards of efficiency, quality, and creativity in the market. Furthermore, as consumer demands evolve towards more personalized and unique products, DTF provides the flexibility needed to satisfy these trends.

Looking ahead, the visibility of DTF technology within the industry will likely increase, prompting further educational opportunities and community engagement initiatives. Businesses that proactively learn and adapt to the changing landscape of DTF printing will be well-positioned to capitalize on emerging trends and innovations. As more professionals recognize its capabilities, DTF technology will continue to shape the future of textile printing, offering exciting possibilities for both large-scale manufacturers and individual creators alike.

Frequently Asked Questions

What are the main advantages of DTF Transfers in textile printing?

DTF Transfers, or Direct-to-Film printing, offer several significant advantages. These include versatility in printing on various fabrics such as cotton and polyester, cost-effectiveness for short runs compared to traditional screen printing, and the ability to produce high-quality, intricate designs that maintain vibrant colors and fine details.

How does the DTF printing process work?

The DTF printing process involves printing a design onto a special film, which is then transferred onto the desired fabric using heat and pressure. This method ensures high-resolution prints and precise color reproduction, making it ideal for custom apparel and other textile applications.

What makes DTF technology a preferred choice for custom apparel?

DTF technology is preferred for custom apparel due to its ability to print on a diverse range of materials, low costs for small production runs, and exceptional print quality. This flexibility allows businesses to cater to various customer needs while maintaining operational efficiency.

How do recent innovations in DTF technology impact the printing industry?

Recent innovations in DTF technology, such as high-capacity printers and integrated web-to-print platforms, significantly improve production speeds and streamline processes. These advancements help businesses meet growing market demands for personalized and high-quality textile products, enhancing overall customer satisfaction.

What is the difference between DTF printing and other methods like sublimation?

DTF printing differs from sublimation in its adaptability to various fabric types and its cost-effectiveness for smaller orders. While sublimation is limited to specific materials, DTF can be applied to a broader range of textiles, making it a flexible option for businesses looking to innovate their printing methods.

Why should businesses consider investing in DTF technology?

Investing in DTF technology is beneficial for businesses because it allows them to offer high-quality, custom products at competitive prices. As demand for personalized apparel rises, DTF systems enable efficient production and faster turnaround times, making them an essential asset for staying competitive in the textile printing market.

| Key Points | Details |

|---|---|

| DTF Printing Overview | DTF (Direct-to-Film) transfers images onto textiles using a special film, producing high-quality, vibrant prints. |

| Key Advantages of DTF | 1. Versatile on various materials like cotton and polyester. 2. Cost-effective for small runs compared to traditional methods. 3. High quality and detail in designs. |

| Recent Developments | 1. Improved capacity with new high-speed printers (e.g., Eazydtf). 2. Streamlined web-to-print platforms (e.g., Snuggle DTF). 3. Educational webinars for industry professionals (e.g., GJS webinars). 4. Comparisons showcasing benefits over sublimation. |

| Future of DTF | The DTF technology landscape is evolving, with significant investments and innovations indicating a strong future in the textile printing industry. |

Summary

DTF Transfers are revolutionizing the textile printing industry by offering a versatile and efficient method for transferring high-quality designs onto fabrics. As businesses and crafters increasingly adopt this technology, DTF enables vibrant prints on various materials while remaining cost-effective for small orders. The ongoing advancements in DTF, such as enhanced production capabilities, innovative platforms, and educational initiatives, position it as a strong competitor in the printing market, promising a bright future for personalized and creative textile applications.