DTF transfers, or Direct to Film transfers, are rapidly becoming a game-changer in the custom apparel printing world. This innovative technique allows for vibrant, high-quality designs to be easily applied to various fabrics, making it a favorite among both small business owners and DIY enthusiasts. The process of DTF printing involves using specialized equipment to create precise and intricate images, setting a new standard in textile decoration. As the demand for personalized clothing continues to rise, understanding DTF transfers has never been more essential for those looking to succeed in the competitive apparel market. Whether you’re a beginner or a seasoned professional, this guide will help you navigate the exciting possibilities that DTF printing offers.

When exploring methods for custom garment decoration, one cannot overlook the transformative power of Direct to Film (DTF) printing techniques. Often referred to by various terms such as film transfers and garment heat transfers, this approach harnesses cutting-edge technology to produce striking designs with minimal effort. Unlike traditional printing methods, which may involve complex processes such as screen printing, DTF printing streamlines the workflow and opens doors to creative innovations. With an array of DTF printing equipment available, anyone eager to delve into custom apparel printing can quickly find suitable resources for success. Join us as we dive deeper into the world of DTF transfers, revealing tips and insights tailored for beginners and experts alike.

Understanding DTF Transfers: The Future of Custom Printing

DTF transfers, or Direct to Film transfers, are revolutionizing the custom printing industry by offering a seamless way to transfer intricate designs onto fabrics. This process involves printing onto a film and then applying it to the garment using heat, making it a perfect choice for various fabric types. Unlike traditional printing methods, the DTF approach allows for bright colors and detailed graphics to pop with clarity. It has quickly gained popularity among both professional printing businesses and hobbyists seeking vibrant results in their apparel printing.

What sets DTF apart from other custom printing avenues is its simplicity and high quality. Artists can confidently create detailed artworks without the hassle of weeding that traditional vinyl printing requires. As more individuals and businesses seek unique and personalized apparel, DTF transfers are positioned well to cater to this growing demand. Whether producing a few items for a family reunion or bulk orders for a sports team, DTF offers flexibility that caters to different printing needs.

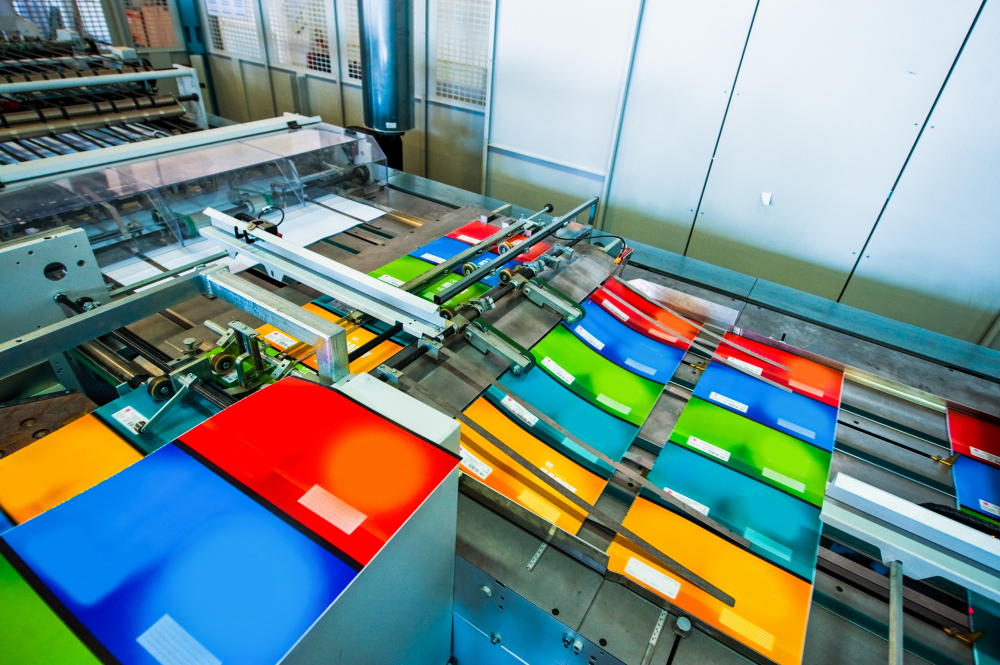

Essential Equipment for Successful DTF Printing

To embark on your DTF printing journey, you will need several essential pieces of equipment to ensure high-quality results. The most crucial item is a specialized DTF printer capable of printing vibrant colors directly onto transfer film. This printer uses pigment-based inks that adhere well to materials, allowing for outstanding imagery on various fabrics. Additionally, a reliable heat press is necessary to apply the transfers accurately, ensuring that the design sticks well to the garment without damage.

Apart from the printer and heat press, you will also require quality transfer film and adhesive powder. The transfer film is specifically designed to accept the printed design and must be compatible with the type of ink used. Furthermore, the adhesive powder is vital to bond the ink with the fabric during the heat-pressing process, promoting durability and longevity. Having quality supplies ensures that your DTF transfers not only look great but also withstand daily wear and tear, making your products desirable in the custom apparel marketplace.

Mastering the DTF Printing Process: A Step-by-Step Guide

Embarking on DTF printing requires an understanding of the detailed step-by-step process to achieve quality results. Begin by creating your designs with software like Adobe Illustrator, ensuring your graphics are of high resolution. After getting your artwork ready, the next step is to print your design on transfer film using your DTF printer. It’s essential to use the correct printer settings to maximize color vibrancy and print quality.

Once the design is printed, the application of adhesive powder is next. While the ink is still wet, carefully sprinkle the powder over the design, as this will create a strong bond once cured. Following that, the transfer must be cured with heat according to specific guidelines. The final step involves pressing the transfer onto the garment using the heat press, which sets the design into the fabric. This thoughtful process exemplifies not only the beauty of DTF printing but also its efficiency, making it an attractive option for custom apparel makers.

Cost Considerations: Budgeting for DTF Transfers

When launching a DTF printing venture, understanding the associated costs is critical for budgeting and planning. Initial investments can range widely from a few hundred to several thousand dollars, depending on the equipment quality and brand selection. Therefore, aspiring business owners need to prioritize key equipment like a reliable printer, heat press, transfer films, and adhesive powders, which collectively represent the bulk of startup costs.

Ongoing material costs should also be factored into your budget. Regular purchases of transfer films and adhesives can accumulate quickly, yet they will reduce as your workflow stabilizes. Overall, while the initial setup may seem daunting, effective cost management and production efficiency can lead to significantly lower costs per transfer compared to other methods in the long term, ultimately improving your profit margins.

Current Market Trends in DTF Transfers

The market for DTF transfers is expanding rapidly, driven by a rising demand for personalized apparel. From sports teams wanting custom uniforms to businesses aiming to create unique promotional items, DTF printing provides a viable solution for various clients. Many consumers now seek out quality and individuality in their clothing, with DTF transfers standing out due to their affordability and vibrant results, making them increasingly popular in custom apparel.

As fashion technology continues to evolve, DTF transfers offer powerful advantages that attract small business owners and entrepreneurs. The ability to create custom designs with minimal restrictions has led to a surge in provision for retail and online businesses specializing in unique prints. Keeping abreast of these market trends ensures that those engaged in DTF printing can seize opportunities and cater to a diverse clientele.

Helpful Tips for Beginners in DTF Printing

Starting a journey with DTF printing can be overwhelming, especially for beginners. One of the best ways to ease into it is by starting small with simple designs. This approach allows you to familiarize yourself with the process without becoming overwhelmed, gradually building your confidence and skills. Additionally, don’t hesitate to test different brands of transfer films and adhesive powders to determine the best fit for your specific printing needs.

Another crucial tip for beginners is to stay informed about the latest advancements in DTF technology and trends. Regularly visiting industry-related blogs, forums, and social media groups can provide valuable insights and new techniques that can enhance your printing capabilities. As you progress in your DTF printing journey, continuous learning will be instrumental in refining your methods and maintaining a competitive edge.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, involves creating transfers by printing designs onto a specialized transfer film. These designs are then heat pressed onto fabric, allowing for vibrant colors and detailed graphics on various materials like cotton and polyester.

What equipment do I need for DTF transfers?

To start with DTF transfers, you’ll need a DTF printer that uses pigment-based inks, a reliable heat press, transfer film for printing designs, and adhesive powder to bond the print to the fabric. This equipment ensures high-quality and durable results.

Can beginners use DTF transfers for custom apparel printing?

Yes, DTF transfers are beginner-friendly for custom apparel printing. With straightforward processes and no weeding required, newcomers can achieve professional results by following essential steps like printing, applying adhesive, and heat pressing.

What are the advantages of using DTF transfers over traditional printing methods?

DTF transfers offer several advantages, including superior color vibrancy, the ability to print intricate designs without weeding, versatility across different fabric types, and a durable finish that resists fading and cracking over time.

How can I ensure high-quality results with my DTF printing setup?

For high-quality DTF printing, ensure you use the correct printer settings, invest in quality transfer films and adhesive powders, and regularly maintain your equipment. Experimenting with designs can also improve your understanding of achieving optimal results.

What trends are currently shaping the DTF transfers market?

The DTF transfers market is seeing a rise in demand for custom apparel, particularly personalized clothing for events, businesses, and sports teams. DTF printing’s affordability and quality make it an attractive option for small business owners looking to capitalize on this growing trend.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers print designs onto film and then transfer to garments using heat, offering versatility and vibrant colors across fabrics like cotton and polyester. |

| Advantages of DTF Transfers | High quality, versatility across fabrics, durability, and no weeding required. |

| Essential Equipment | Printer, heat press, transfer film, and adhesive powder. |

| Cost Considerations | Initial investments can range from hundreds to thousands of dollars; however, costs decrease with steady workflow. |

| Market Trends | Increase in personalized clothing and growing demand for custom apparel. |

| Tips for Beginners | Start small, test supplies, and stay updated with industry trends. |

| Additional Resources | Printful Blog, InkSoft, Create! Mag for further learning. |

Summary

DTF Transfers have made a significant impact in the world of custom printing, establishing themselves as a go-to option for both hobbyists and small business owners. This innovative printing technique allows users to create high-quality, vibrant designs on various fabric types with ease. The advantages of DTF transfers, such as their durability and the elimination of weeding, make them a hassle-free choice compared to traditional methods. As the demand for personalized apparel continues to rise, exploring DTF transfers could open up new opportunities, allowing individuals to stay ahead in the competitive custom apparel market. With the right knowledge and equipment, anyone can dive into the exciting realm of DTF printing and unleash their creativity.