DTF Transfers, which stands for Direct-to-Film transfers, have revolutionized the custom apparel printing landscape with their vibrant and durable print capabilities. As businesses seek innovative ways to meet consumer demands for high-quality prints, DTF printing stands out because it can handle a wide range of fabrics, from cotton to blends. This method allows for engaging designs that maintain integrity and charm across various material types, setting it apart from traditional screen printing and DTG printing techniques. In this article, we will delve into the unique advantages of DTF Transfers and how they compare to older methods, providing insights that can help you choose the right printing solution for your needs. Whether you’re a designer or a small business owner, understanding the nuances of these printing techniques will empower you to make informed decisions in your custom apparel journey.

Direct-to-Film (DTF) transfers represent a cutting-edge innovation in the world of fabric printing, appealing to both small brands and large-scale manufacturers. This modern technique involves transferring designs via a specialized film, ensuring excellent results on various textiles. In contrast to conventional screen printing methods, DTF boasts superior versatility and the capacity to work with diverse fabric types, contributing to its growing popularity in custom apparel production. Additionally, advancements in printing technology have made DTF more accessible, allowing for swift order fulfillment and reduced inventory waste. By examining the features and benefits of DTF alongside other popular methods, such as DTG and screen printing, we can uncover the best fit for your artistic vision and business objectives.

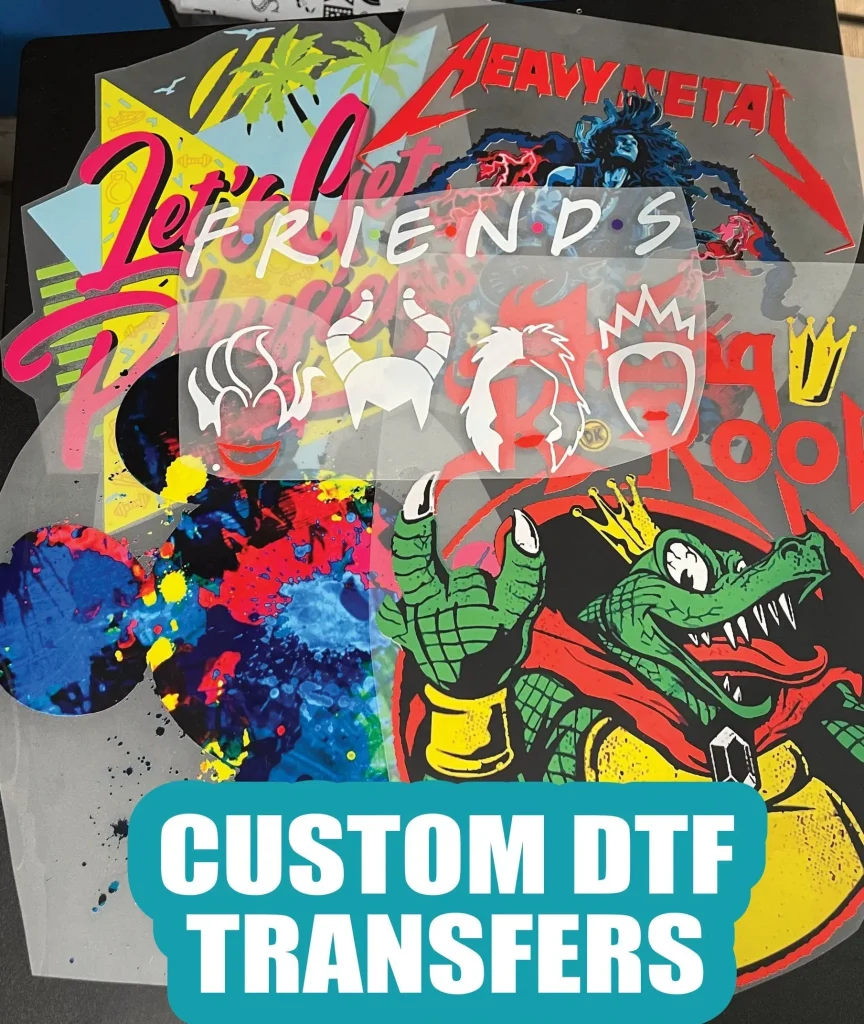

Understanding the Basics of DTF Transfers

DTF transfers, or Direct-to-Film transfers, represent a groundbreaking technique in the world of custom apparel printing. This process allows for intricate designs to be printed onto a special PET film before being heat-pressed onto various fabric surfaces. What sets DTF apart is its ability to work on a wide array of materials, from cotton to polyester and even spandex blends, offering unmatched versatility that many traditional methods lack.

The growing acceptance of DTF transfers in the market can be attributed to revolutionary developments in printing technology. With brands like Insta Graphic Systems leading the charge, DTF has established itself as a reliable choice for businesses looking to deliver high-quality and vibrant prints. As companies pivot to adopt these advanced printing methods, it’s essential to consider how DTF can enhance the customization process, allowing for personalized designs that resonate with customers.

Comparing DTF with Screen Printing

Screen printing has long been a favored method for custom apparel due to its durability and vibrant color output. However, it requires a specific fabric compatibility, typically excelling on cotton and polyester. In contrast, DTF transfers handle a broader range of materials with ease, making it an appealing alternative for businesses needing flexibility in their offerings. This adaptability enables designers to experiment with different fabric combinations without worrying about print compatibility.

Moreover, while screen printing may deliver striking colors, the setup process can be tedious and time-consuming, especially for smaller batches. DTF printing simplifies this by reducing the time needed to prepare designs and allowing for on-demand production without significant waste. This not only supports sustainability efforts but also enhances operational efficiency, aligning well with the fast-paced demands of today’s market.

DTF Transfers vs. DTG Printing

Direct-to-Garment (DTG) printing is yet another contender in the custom printing arena, known for its exceptional ability to capture intricate details in designs. However, DTF transfers offer a quicker setup time and can yield high-quality results on multiple fabric types, including those that DTG may struggle with. Businesses looking to diversify their product offerings may find DTF to be a more versatile option that complements, rather than competes with, DTG technology.

Looking at production speed, DTF has the upper hand, particularly for small runs or rapid prototyping. Since DTG requires direct garment interaction, it can lead to longer wait times, whereas DTF prints can be prepared and transferred efficiently. Understanding these nuances helps businesses tailor their printing choices to meet specific client demands, allowing for more personalized and timely services.

Cost Analysis of DTF Transfers

The cost of investing in DTF transfer technology often raises questions for businesses, especially when comparing it to traditional screen printing and DTG. While the initial setup and equipment costs may be higher, the ability to perform quick production runs without the need for extensive inventory can lead to long-term savings. DTF’s efficiency in reducing material waste and eliminating excess stocks makes it a financially prudent choice for many small to medium-sized businesses.

Moreover, as customer demands lean towards more customized apparel solutions, DTF printing provides the flexibility to accommodate various order sizes without incurring disproportionate costs. This scalability ensures that businesses can remain profitable while providing high-quality outputs that satisfy consumer preferences, all while adhering to budget constraints.

Limitations of DTF Transfers in Custom Apparel

Despite the numerous advantages offered by DTF transfers, it’s important to recognize potential limitations. For instance, while DTF prints are generally durable, feedback suggests that they may not withstand the rigors of repeated washes as effectively as screen-printed items. This could be a critical consideration for customers who prioritize long-lasting apparel, particularly in high-use scenarios.

Additionally, achieving certain vibrant colors can be trickier with DTF compared to screen printing or DTG. Accurate color reproduction requires expertise in color management, which can vary by brand and product type. For businesses targeting markets that demand impeccable color fidelity, it’s crucial to weigh these limitations against the benefits DTF offers when finalizing the printing method.

Choosing the Right Printing Technique for Your Needs

Deciding between DTF transfers, screen printing, and DTG printing ultimately hinges on your specific needs and goals. If versatility, quick turnaround times, and flexibility across various fabric types are critical for your business, DTF transfers stand out as an excellent option. On the other hand, if you are focused on producing large quantities of robust garments with a classic finish, traditional screen printing may still hold its ground.

It’s essential to analyze customer expectations, the types of designs you plan to print, and the volume of orders you anticipate to ensure you choose the most suitable printing technique. Each method has its unique strengths and weaknesses, and understanding these will empower you to make an informed decision that aligns with your company’s vision for custom apparel solutions.

Frequently Asked Questions

What are DTF transfers and how do they compare to screen printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs on a special film and then transferring them to fabric using heat. Compared to screen printing, DTF offers greater versatility in fabric compatibility, allowing designs to adhere to various materials, including cotton and polyester blends.

How does DTF printing produce vibrant colors compared to DTG printing?

DTF printing is designed to achieve vibrant colors by using a special printing process that transfers ink onto a film before applying it to the fabric. While DTG printing offers high detail and color accuracy, DTF can produce comparable vibrancy, especially when using high-quality inks and color management techniques.

Is DTF printing suitable for all types of fabrics?

Yes, DTF printing boasts exceptional fabric compatibility. Unlike traditional screen printing, which primarily works best with cotton and polyester, DTF can successfully transfer designs onto a wide range of materials, including blends and synthetic fabrics, making it a versatile choice for custom apparel.

What advantages does DTF transfer printing offer for custom apparel businesses?

DTF transfer printing provides several advantages for custom apparel businesses, including quick setup times, reduced material waste, and the ability to handle on-demand orders effectively. This flexibility allows businesses to keep inventory low while meeting customer demands swiftly.

Are DTF transfers as durable as screen prints?

While DTF transfers are durable, they may not endure the same wear and tear as high-quality screen prints. The durability of DTF prints can vary based on the quality of the inks used and the application process, but overall, care should be taken to maintain their longevity.

What are the cost implications of choosing DTF transfers over other printing techniques?

The initial investment for DTF transfer printing equipment can be higher than traditional screen printing or DTG setups. However, the flexibility and reduction in excess inventory can lead to long-term cost savings, particularly for small runs or custom orders, as businesses can minimize waste.

| Criteria | DTF Transfers | Screen Printing | DTG Printing |

|---|---|---|---|

| Versatility and Fabric Compatibility | High versatility, suitable for various fabrics including cotton, polyester, and blends. | Limited mainly to cotton and polyester. | Primarily designed for cotton, less effective on other fabrics. |

| Setup and Production Speed | Quick setup allows for on-demand printing, minimizing inventory waste. | More time-consuming setup; not ideal for smaller orders. | Fast, direct garment printing with minimal setup time. |

| Cost Efficiency | Higher initial equipment costs, but potential for cost savings in reduced waste. | Lower initial investment, but can result in larger material waste for small runs. | Cost-efficient for detailed designs, but costs can add up for large volumes. |

| Durability | May not be as durable as screen prints after multiple washes. | Highly durable, ideal for frequent use. | Good detail, but durability can vary based on fabric and care. |

| Color Fidelity | Excellent, but requires careful color management for vibrant results. | Superior color vibrancy and consistency, especially in large runs. | Exceptional at reproducing fine details and color gradients. |

Summary

DTF Transfers have emerged as a modern solution for custom apparel printing, providing vibrant prints and excellent versatility across a range of fabric types. With quick setup and efficient production speeds, DTF transfers represent a significant advancement in the printing industry. While they offer compelling benefits such as reduced waste and compatibility with mixed fabrics, it’s important to weigh these against potential limitations like durability and color fidelity. Ultimately, choosing the right printing method—be it DTF, screen printing, or DTG—depends on your specific needs, including fabric choice, design complexity, and order volume.