DTF transfers, or Direct-to-Film transfers, are rapidly emerging as a revolutionary technique in the world of custom apparel printing. This cutting-edge DTF printing technology combines the ease of use with impressive durability, allowing vibrant designs to seamlessly transfer onto a variety of fabrics. As businesses seek high-quality custom prints that resonate with their audience, DTF emerges as a versatile and cost-effective solution for diverse printing needs. Additionally, this eco-friendly printing method is garnering attention for its minimal environmental impact compared to traditional methods, making it a popular choice for modern businesses. With the demand for unique and personalized apparel soaring, the role of DTF transfers in transforming custom printing cannot be overstated.

Custom printing is undergoing a transformation, and one of the most notable advancements is the Direct-to-Film transfer method. This innovative technology allows for high-quality images to be printed on various materials, catering to the burgeoning market of custom apparel. Businesses are increasingly turning to this contemporary solution, as it supports eco-friendly practices while also delivering stunning, long-lasting prints. As we explore the dynamics of this Direct-to-Film technique, it becomes clear how it reshapes the landscape of personalized fashion and addresses the demands of both consumers and environmental advocates alike.

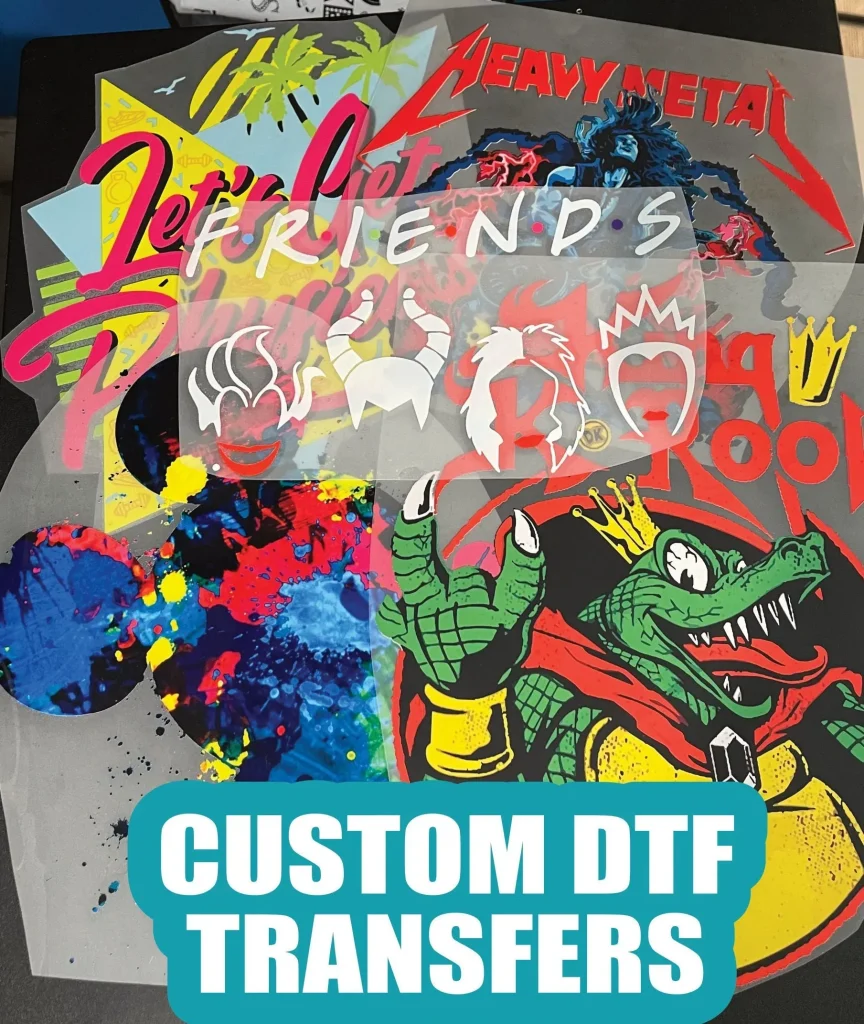

The Rapid Rise of DTF Printing Technology

DTF printing technology has quickly gained traction in the custom printing industry thanks to its innovative approach to transferring designs onto fabric. This method enables vibrant, detailed prints that can withstand the rigors of everyday wear. Businesses are increasingly adopting DTF because it allows for printing on a wider array of materials, including cotton, polyester, and blends, making it a versatile choice for various applications. As consumers seek high-quality custom apparel and unique designs, DTF is setting itself apart as a leading solution.

The market’s enthusiasm for DTF transfers is evident in the recent rise in corresponding printer and ink sales. Entrepreneurs and established businesses alike recognize the opportunities presented by DTF technology. It’s not just about enhancing print quality; it’s about meeting consumer demands for customization and creativity. As these trends continue to evolve, the adoption of DTF printing is expected to accelerate, solidifying its position as a game-changer in the custom apparel printing sector.

Versatility: DTF Transfers Across Multiple Materials

One of the most significant advantages of DTF transfers is their remarkable versatility across different material types. Unlike traditional printing methods, which may be limited in terms of fabric compatibility, DTF can seamlessly adhere to a wide range of textiles. This flexibility empowers businesses to expand their product offerings, catering to diverse consumer preferences. Whether you’re creating custom t-shirts, hoodies, or even bags, DTF technology ensures that your designs maintain their integrity and vibrancy on various fabrics.

This adaptability makes DTF transfers an appealing option for both startups and established companies, as it enables them to experiment with different materials. Brands can diversify their offerings without the risk of compromising print quality or wasting resources. Furthermore, this characteristic is especially beneficial in an era where customers increasingly seek personalized products. DTF transfers allow businesses to tap into these consumer desires effectively, creating a pathway to greater customer satisfaction and loyalty.

The Eco-Friendly Edge of DTF Printing

As sustainability becomes a focal point for modern businesses, DTF printing distinguishes itself by offering eco-friendly printing methods that minimize waste. The DTF process is designed to use fewer resources during setup and production compared to traditional printing techniques. This reduction in resource consumption not only benefits the environment but also enhances a company’s reputation among environmentally conscious consumers.

Furthermore, the ability to print smaller batches without extensive waste aligns perfectly with the growing demand for custom apparel in the marketplace. Consumers are increasingly prioritizing eco-friendly options in their purchasing decisions, making the adoption of DTF printing advantageous for businesses aiming to appeal to this conscientious demographic. By choosing DTF transfers, companies can promote their brand as a leader in sustainable practices while providing high-quality custom prints that resonate with their customers.

Quality and Durability: DTF Transfers Stand Out

Quality is paramount in custom printing, and DTF transfers excel in delivering high-caliber results that appeal to discerning customers. The technology produces vibrant, bold colors that remain intact even after multiple washes, ensuring that the designs will last. This durability is particularly attractive in the competitive market of custom apparel, where consumers expect longevity and value in their purchases.

In a landscape where many printing methods are plagued by issues such as fading, cracking, or peeling, DTF printing offers a reliable alternative. Brands that invest in DTF transfers can assure their customers of lasting quality, thus enhancing overall customer satisfaction. When customers recognize the superior quality of DTF prints, they are more likely to become repeat buyers, fostering long-term loyalty for businesses that prioritize quality in their offerings.

Market Trends: The Future of Custom Apparel Printing

The shift towards DTF printing is not just a passing fad; it reflects significant market trends that emphasize the need for customization and efficiency. As e-commerce continues to dominate the retail landscape, businesses are increasingly looking for printing solutions that can support small-batch production and rapid turnarounds. DTF transfers align perfectly with this need, allowing companies to meet consumer demands for personalized items without incurring hefty costs.

Moreover, as digital technology advances, we can expect DTF printing to become even more integrated into online business models. The rise of print-on-demand services is driving demand for technologies that can support low-cost, high-quality production. DTF transfers will likely remain at the forefront of this movement, enabling entrepreneurs to launch customized merchandise with ease and flexibility.

Getting Started with DTF Transfers: A Guide for Businesses

For businesses considering a foray into the world of DTF transfers, understanding the initial steps is crucial. First, investing in the right DTF printer and material is essential to ensure high-quality results. Additionally, businesses should familiarize themselves with the entire DTF process, from creating designs to executing the transfer on fabric. This knowledge will empower them to maximize the potential of DTF technology and deliver impressive custom apparel to their customers.

Furthermore, companies should explore partnerships with suppliers who offer DTF ink and film, as quality materials play a significant role in the end product. Engaging in creative brainstorming sessions to develop unique designs can also set businesses apart in a crowded market. By leveraging DTF transfers effectively, companies can establish themselves as leaders in custom apparel, maintaining a competitive edge in an ever-evolving industry.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are an innovative printing method that involves printing vibrant images onto a special film, which is then transferred onto fabric. This technique enables high-quality custom prints on various materials, including cotton and polyester, making it a versatile choice for custom apparel printing.

Why are DTF transfers considered eco-friendly printing methods?

DTF transfers are regarded as eco-friendly printing methods because they reduce waste by minimizing the resources required for setup and execution. This approach lowers the environmental footprint associated with custom printing, aligning with the growing demand for sustainable practices in the industry.

What advantages do DTF printing technology offer over traditional printing methods?

DTF printing technology offers numerous advantages over traditional methods like screen printing, including versatility with materials, user-friendly processes, vibrant colors, enhanced durability, and cost-effectiveness, making it an ideal option for custom apparel businesses looking for high-quality custom prints.

How do DTF transfers ensure high-quality custom prints?

DTF transfers ensure high-quality custom prints through their ability to produce vibrant colors and detailed images that remain intact after multiple washes. The technology allows for precise printing on various fabrics, providing longevity and durability that is essential for custom apparel.

What factors contribute to the rising popularity of DTF transfers in the custom printing market?

The rising popularity of DTF transfers in the custom printing market is attributed to their versatility across materials, impressive print quality, cost-effectiveness for small batches, suitability for e-commerce growth, and alignment with eco-friendly printing methods, making them an attractive option for businesses.

Can DTF printing technology support small businesses in custom apparel printing?

Yes, DTF printing technology can significantly support small businesses in custom apparel printing. Its user-friendly process, cost-efficiency, and capacity for small batch production allow emerging brands to cater to custom orders without high financial investment, fostering growth in the competitive market.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers utilize film to transfer images onto textiles, competing effectively with traditional methods. |

| Key Advantages of DTF Transfers | 1. Versatile with various materials (cotton, polyester, blended). 2. User-friendly and requires minimal setup, ideal for startups. 3. High-quality prints that resist fading and peeling. 4. Cost-effective for small batch printing. 5. Ideal for e-commerce and digital print-on-demand models. |

| Market Trends | Increasing adoption of DTF technology for sustainable practices and improved production efficiency. |

| Sustainability | DTF printing reduces waste and resource consumption compared to traditional methods, appealing to eco-conscious consumers. |

| Technology Enhancements | Continual advancements in DTF printing hardware and materials, making it easier for businesses to produce high-quality outputs. |

Summary

DTF transfers are revolutionizing the custom printing industry by offering unparalleled versatility and quality. This innovative printing method allows businesses to print on a variety of materials while ensuring vibrant, long-lasting designs. As companies pivot to meet consumer demand for personalized, eco-friendly products, DTF transfers provide an efficient solution that balances cost and performance. With the growing focus on sustainability and technological advancements in the printing sector, DTF transfers are likely to dominate the landscape, serving as a critical resource for businesses aiming to thrive in a competitive market.