DTF Transfers, or Direct to Film transfers, are revolutionizing the world of custom apparel printing by combining innovative techniques with user-friendly applications. This cutting-edge method allows for vibrant and durable designs to be effortlessly transferred onto a variety of fabrics, offering unparalleled versatility in garment production. With DTF printing, businesses and creators can enjoy a streamlined process that eliminates many complications of traditional printing methods, like screen printing. In this ultimate guide, we will explore essential DTF transfer techniques, helpful DTF printing tips, and the latest trends shaping the industry. Whether you’re a seasoned pro or just starting out, mastering the art of DTF transfers can elevate your printing projects to new heights.

Unveiling the world of Direct to Film printing, this guide delves into the techniques behind successful custom textile applications. Known for its groundbreaking approach, this printing method allows designers to create dynamic graphics with ease on an array of fabrics. By leveraging advanced DTF transfer processes, print professionals can achieve high-quality, intricate designs without the fuss associated with older techniques. With insights on how to optimize your DTF printing experience, including best practices and essential tips, this comprehensive overview caters to both novices and experts seeking to enhance their skills in lucrative custom apparel printing.

Understanding DTF Printing Techniques

DTF printing techniques have gained popularity due to their efficiency and ability to produce high-resolution prints. Unlike traditional methods such as screen printing, DTF transfers allow for seamless printing of complex designs without extensive setup. This process begins with printing designs onto specialized DTF transfer films, followed by the application of adhesive powder that bonds the ink to the fabric. Understanding these techniques is essential for maximizing the potential of custom apparel printing.

In addition to the basic DTF printing process, mastering various transfer techniques can enhance the quality of your final product. Techniques such as adjusting the ink load for richer colors, optimizing heat press settings for different fabric types, and experimenting with multiple layers of transfers can lead to unique and vibrant custom prints. By becoming familiar with the nuances of DTF printing, you can efficiently create stunning designs that stand out in the competitive apparel market.

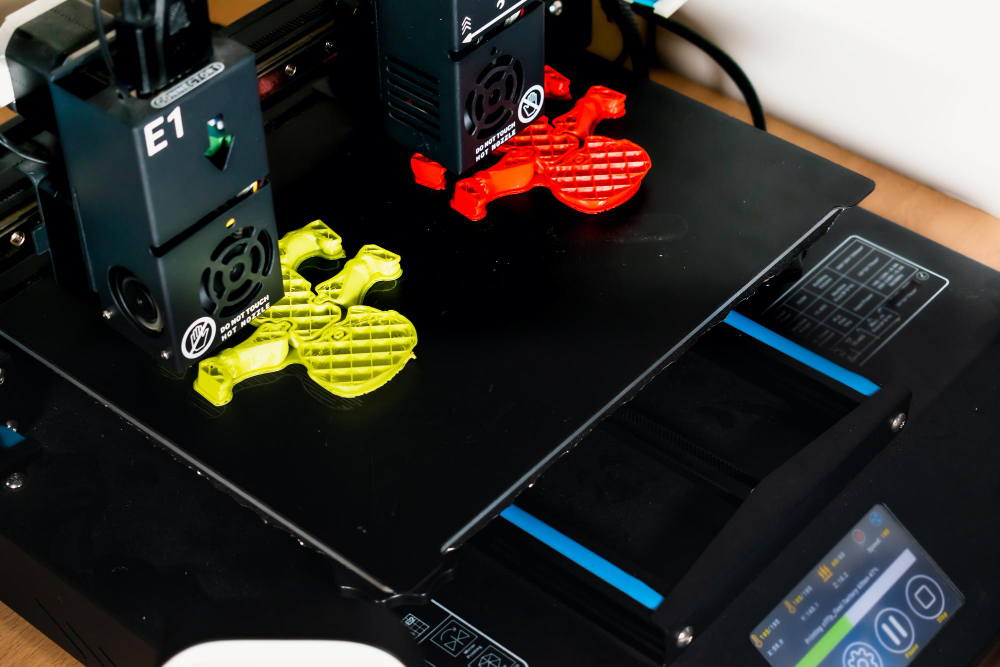

The Essential Equipment for DTF Transfers

To successfully execute DTF transfers, investing in the right equipment is crucial. This includes selecting a dedicated DTF printer that handles water-based inks and is compatible with specific transfer films. Brands like Epson and Mimaki have been frontrunners in producing reliable printers that yield crisp, vivid results. Additionally, a high-quality heat press is indispensable as it ensures that the transfers are applied with the right pressure and temperature, essential for achieving durable prints.

Beyond the printer and heat press, you will also need to consider other important tools such as adhesive powders, specialized inks, and transfer films. Each component plays a pivotal role in the DTF process, and choosing high-grade materials can make a substantial difference in the outcome of your prints. Focusing on these essentials allows you to create custom apparel with confidence, knowing that your equipment is set up for success.

DTF Transfer Techniques for Custom Apparel Printing

When it comes to custom apparel printing using DTF transfers, mastering the various techniques can significantly elevate your output quality. One important technique is the use of vibrant, high-opacity inks that yield outstanding color results on both light and dark fabrics. Additionally, applying the right amount of adhesive powder creates a robust bond that ensures durability, preventing cracking and peeling over time.

DTF transfer techniques also extend to the design itself. Utilizing color gradients, intricate patterns, or even mixed media can differentiate your apparel from competitors. Coupling these design strategies with precise printing methods—synchronizing ink settings and heat application—can result in garments that not only look great but also stand the test of time wash after wash.

Key Tips for Successful DTF Printing

As you venture into DTF printing, there are several key tips to keep in mind for achieving successful results. First, always ensure that your DTF printer is properly calibrated to support optimal color output for your designs. Regular maintenance and cleaning of the printer head can prevent any inconsistencies in ink flow, which is vital for perfect prints. Furthermore, utilizing high-quality transfer films specifically designed for DTF processes ensures better adhesion and clearer imagery on the fabric.

Another critical tip is to practice patience during the heat pressing process. Ensuring that the heat and pressure are applied correctly is essential for the success of your transfers. Too much pressure can damage the fabric, while too little may prevent proper adhesion. Taking the time to conduct tests on scrap materials can save you time and resources, allowing you to fine-tune your technique before moving on to more valuable custom apparel.

Exploring Recent Trends in DTF Printing

The DTF printing industry is evolving continuously, influenced by emerging trends that reshape its landscape. One significant trend is the increasing focus on sustainability. Manufacturers are now prioritizing environmentally-friendly inks and materials, allowing businesses to cater to eco-conscious consumers. By integrating sustainable practices into your DTF printing operations, not only can you enhance your brand image, but you may also open up new market opportunities.

Additionally, as more individuals and businesses discover the benefits of DTF printing, the market is experiencing substantial growth. The demand for customized prints on textiles is rising, which encourages innovations in DTF technology. Staying informed about these trends can help you leverage advancements, such as improved ink formulations or enhanced transfer films, ultimately leading to higher quality outputs and greater customer satisfaction.

Leveraging Community Resources for DTF Success

The DTF printing community offers a wealth of resources that can significantly streamline your journey towards mastering this printing technique. Online forums, instructional videos, and blogs are filled with tips, troubleshooting advice, and recent innovations in DTF technology. Engaging with fellow printers can not only provide you with actionable insights but also foster a supportive network that helps enhance your printing skills over time.

Moreover, participating in community discussions or attending workshops can introduce you to new ideas and techniques that aren’t widely known. These connections can also lead to collaboration opportunities, where you can gain practical experience and share your knowledge. By leveraging community resources effectively, you set yourself up for a long-term growth trajectory in the competitive world of DTF printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing method that allows for high-quality designs to be printed on transfer film and then applied to various fabrics. The process involves printing your design onto a special film using a DTF printer, applying an adhesive powder, and then using a heat press to transfer the design onto the fabric, resulting in vibrant and durable prints.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers numerous benefits for custom apparel, including the ability to print full-color designs without the need for a white underbase. This method is versatile, working well on both dark and light fabrics. Additionally, DTF transfers support intricate designs and are generally easier and faster than traditional screen printing, making them a favorite for custom apparel production.

How do I choose the right printer for DTF transfers?

When selecting a printer for DTF transfers, it’s essential to choose one specifically designed for this technique. Look for printers, such as those from Epson or Mimaki, that support the use of water-based inks suitable for DTF printing. A dedicated DTF printer ensures optimal color accuracy and print quality, which is crucial for creating stunning custom designs.

What are some essential DTF printing tips for beginners?

For beginners in DTF printing, start by investing in high-quality inks and films that work well together. Properly prepare your printer settings and ensure that your heat press is set at the recommended temperature (300°F to 330°F) with appropriate pressure. Additionally, focus on post-transfer care by washing printed garments inside out in cold water for longevity of the DTF transfers.

What materials are best for DTF transfers?

DTF transfers work best on a variety of fabrics, with polyester blends often yielding the best results. Fabrics like cotton, polyester, and cotton-poly blends are ideal for DTF printing. Ensure the material is smooth and clean for a successful transfer, as this will enhance the adherence and longevity of your designs.

Are there eco-friendly options available for DTF printing?

Yes, the DTF printing industry is increasingly shifting towards sustainability. Look for manufacturers offering eco-friendly inks and films that minimize environmental impact. Many brands are now promoting recyclable materials and sustainable practices, making it easier for businesses and individuals to engage in eco-conscious custom apparel printing while using DTF transfers.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers simplify transferring high-quality designs onto various materials and are ideal for custom apparel production. |

| Focus Keyword | DTF Transfers |

| Printing Overview | DTF printing allows vibrant, full-color prints on various fabrics without complex setups of traditional methods. |

| Key Techniques and Tips | 1. Choosing the right printer is crucial, prefer brands like Epson and Mimaki. 2. Use water-based inks with high-quality DTF films for optimum results. 3. Apply hot-melt adhesive powder for proper ink adhesion. 4. Set heat and pressure correctly (300°F to 330°F, 10-15 seconds). 5. Allow transfers to cool before peeling and follow washing instructions to preserve quality. |

| Recent Developments | Growth in market demand for custom textile printing and trends towards sustainable practices are shaping the future of DTF printing. |

Summary

DTF Transfers have transformed the printing landscape, providing an efficient way to create high-quality custom designs on various fabrics. This innovative technology allows for vibrant, detailed prints without the limitations of traditional methods, offering unique advantages such as ease of setup and versatility. By mastering key techniques, utilizing the right materials, and keeping up with industry trends, anyone can achieve stunning results in their custom apparel production. As more individuals and businesses embrace DTF Transfers, the potential for creativity and market growth continues to expand.