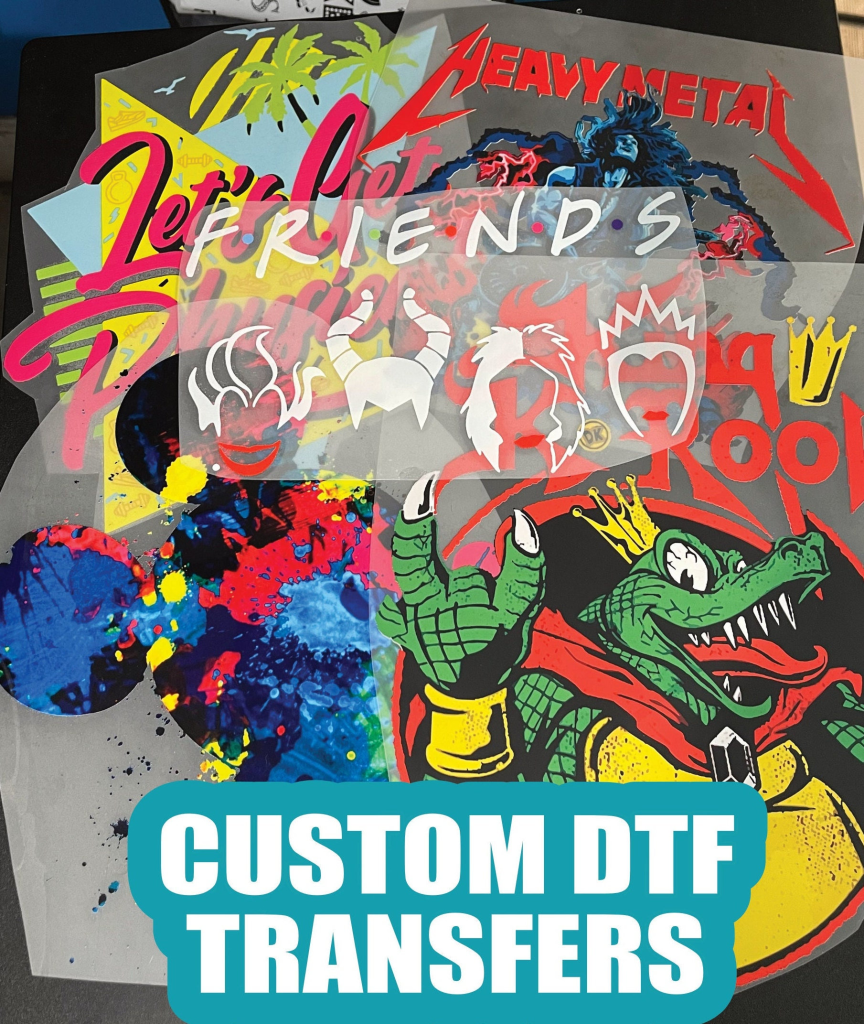

DTF transfers, or Direct to Film transfers, are transforming the landscape of fabric printing with their precision and versatility. This innovative technique combines the best aspects of digital printing and heat transfer, enabling artists and businesses to create vibrant, long-lasting designs on a variety of materials. Understanding the DTF printing process can significantly enhance your productivity, whether you’re a professional printer or a DIY enthusiast looking to add a personal touch to your creations. In this article, we will explore essential DTF transfer tips to help you achieve flawless results every time, ensuring that your prints not only look great but also stand the test of time. Join us as we dive into the world of DTF transfer materials, printer settings, and effective heat press techniques that can elevate your projects to the next level.

Direct to Film printing, commonly referred to as DTF transfer, is rapidly gaining popularity in the custom apparel industry for its ability to reproduce intricate designs with remarkable detail. This process involves using a specific type of film that is printed upon and later applied to fabrics using a heat press, making it a preferred choice for decorators keen on quality and durability. The DTF printing technique simplifies the transfer of vibrant colors onto various materials, unlocking new creative possibilities for both personal and commercial projects. By harnessing the right DTF transfer tips, materials, and techniques, you can ensure that every project you undertake results in stunning, professional-quality prints. As you navigate the essential steps of the DTF process, remember that understanding the nuances of your equipment and materials will lead to the best outcomes.

Understanding DTF Transfer: A Revolutionary Technique

DTF transfer, or Direct to Film transfer, is a cutting-edge printing method that has transformed the way intricate designs are applied to garments. By printing designs onto a special film and transferring them onto fabric with heat and pressure, DTF provides unmatched clarity and vibrancy in prints. This method allows for multiple colors and fine details to be replicated consistently, making it a preferred choice for custom apparel and merchandise.

One of the standout features of DTF transfer is its versatility. Unlike traditional screen printing, which can be limiting in terms of color combinations, DTF allows for a more diverse palette and can be applied to various materials including cotton, polyester, and blends. This flexibility not only caters to a broader market but also enables artists and businesses to experiment with their designs and provide unique offerings.

Choosing Quality DTF Transfer Materials

When diving into the world of DTF transfers, the quality of materials cannot be overstated. The film you select plays a crucial role in how well your prints will adhere to fabrics. Opting for premium DTF films can significantly enhance the absorption of ink and improve the durability of the transfer. Well-known brands like Epson are often recommended due to their reliable performance and high-quality outcomes.

In addition to the film, using DTF-specific inks is vital. These inks are formulated to bond effectively with both the film and the fabric, ensuring that colors remain vibrant and that the prints endure multiple washes without fading or cracking. Prioritizing quality in these materials will set the foundation for achieving extraordinary results in your DTF transfer projects.

Optimizing Printer Settings for DTF Printing

The effectiveness of your DTF transfer largely hinges on printer settings. Fine-tuning your printer can lead to superior print quality. For instance, adjusting the color settings can help achieve vibrant results tailored to the specific type of DTF film being used. Moreover, tweaking ink density can produce more saturated colors, while slower print speeds allow better ink absorption, enhancing detail and overall quality.

Experimentation with settings is an essential part of mastering DTF transfers. Each printer may respond differently to adjustments, making it vital to test out various configurations until you find the sweet spot. Understanding the capabilities of your printer and how they interact with different materials can dramatically elevate your work.

Pre-Treatment for Enhanced Adhesion in DTF Transfers

Pre-treatment is a crucial step in the DTF transfer process, especially for synthetic fabrics that may require additional care. A specialized pre-treatment spray tailored for DTF transfers can significantly improve the adhesion of the transfer to the fabric. This step ensures a long-lasting bond between the transfer and the material, reducing the likelihood of issues such as peeling or flaking during washes.

By implementing a reliable pre-treatment method, users can enhance the longevity of their designs, providing customers with high-quality products that withstand the test of time. This proactive approach ultimately leads to a better end-user experience, enhancing customer satisfaction and loyalty.

Mastering Heat Press Settings for Flawless Transfers

The heat press is indispensable in the DTF transfer process, and configuring its settings correctly is crucial for success. Most DTF transfers require specific temperature and pressure settings—typically, around 320°F (160°C) with medium to firm pressure. Accurate heat distribution during the transfer time, which usually ranges from 10 to 15 seconds, is vital to achieving optimal results.

Improper heat settings can lead to poor adherence, compromised colors, or smudging, ultimately affecting the quality of the transfer. Thus, it’s essential to refer to the instructions accompanying your materials for the best practices, ensuring that each application yields a stunning finish.

Aftercare and Curing: Ensuring Lasting Quality

Once the DTF transfer has been applied, proper aftercare is essential for maintaining the integrity of the prints. Allowing the transfer to cool down properly before peeling the film is a key step known as the cold peel method. This phase significantly contributes to the clarity of the image, helping prevent any residual film from sticking to the fabric, which can detract from the overall finish.

Furthermore, testing a corner of the transfer before fully peeling it can prevent mishaps that could ruin a design. Adhering to this careful approach not only improves the quality of individual pieces but also builds a reputation for excellence, helping to establish trust with clients.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing technique that allows for vivid designs to be printed onto a special film. This film is then heat pressed onto fabric, resulting in vibrant and durable prints. Understanding the DTF printing process is crucial for achieving high-quality results.

What materials are best for DTF transfers?

The best materials for DTF transfers include premium DTF film and high-quality DTF-specific inks. Using quality materials ensures better adhesion and longer-lasting prints, preventing issues like fading and cracking.

What are essential DTF transfer tips for beginners?

Essential DTF transfer tips for beginners include optimizing your printer settings for color and ink density, pre-treating fabrics for better adhesion, and using the correct heat press settings, such as temperature and pressure, during the application process.

How can I optimize my heat press for DTF transfers?

To optimize your heat press for DTF transfers, set the temperature to around 320°F (160°C), apply medium to firm pressure evenly, and press the transfer for 10-15 seconds. Always check the specific instructions for the materials you are using.

What is the curing process for DTF transfers?

After applying a DTF transfer, allow it to cool slightly before peeling the film off. This cold peel method helps ensure clearer images and prevents residual film from sticking to the fabric. Testing a corner before fully peeling is also advisable.

What storage practices should I follow for DTF transfers?

For optimal preservation, store finished DTF transfers in a cool, dry environment away from direct sunlight. This will help maintain the quality and vibrance of the prints, ensuring they last longer.

| Key Points | Details |

|---|---|

| What is DTF Transfer? | A printing technique that transfers designs from a film onto fabric using heat and pressure. |

| Quality Materials Matter | Using high-quality DTF film and inks is crucial for durability and print quality. |

| Printer Settings Optimization | Adjust settings like color profiles and ink density to enhance print results. |

| Pre-Treatment for Better Adhesion | Pre-treating fabrics, especially synthetic ones, improves adhesion of transfers. |

| Heat Press Settings | Use a temperature of 320°F (160°C) with medium to firm pressure for about 10-15 seconds. |

| The Curing Process | Allow cooling before peeling to ensure clarity and adhesion. |

| Storage Tips for Transfers | Store in a cool, dry environment and avoid sunlight to maintain quality. |

| Experiment and Adjust | Test different fabrics and settings to find optimal combinations. |

| Seek Feedback | Gather feedback from clients to improve quality and customer satisfaction. |

Summary

DTF transfers represent a significant advancement in the field of fabric printing, combining precision and versatility to create vibrant designs. By mastering the intricacies of the DTF transfer process, from selecting quality materials to fine-tuning printer settings, anyone can achieve professional-level results. Understanding the importance of pre-treatment and heat press techniques further enhances the quality of the final product. Experimentation plays a vital role in this journey, allowing for personalized adjustments that cater to specific fabrics and preferences. Ultimately, dedication to mastering DTF transfers leads to not only improved outcomes but also heightened client satisfaction and opportunities for creative expression.