DTF transfers, short for Direct-to-Film transfers, have revolutionized the custom printing landscape, offering vibrant and high-quality prints on a vast array of fabrics. This innovative DTF printing process enables artists and crafters to unleash their creativity by easily transferring intricate designs. With a unique adhesive system that bonds ink to fabric, DTF stands out in comparison to traditional methods like sublimation, especially for materials beyond polyester. As the popularity of custom DTF transfers rises, so does the demand for tools and knowledge to master this technique. Dive into the world of crafting with DTF and discover how it can elevate your creative projects to new heights.

Known as Direct-to-Film printing, this modern technique allows for exceptional design transfers onto various textiles. The DTF printing method not only simplifies the printing process but also provides versatility unmatched by older methods, such as screen printing or heat transfer vinyl. As creators look for alternative avenues to express their artistry, DTF emerges as a compelling choice for custom garment production. Additionally, its adaptability to different fabric types broadens the scope for innovative applications across various crafting projects. As we explore the benefits and compare DTF with sublimation, it becomes evident that this printing solution is tailored for the modern crafter.

Understanding DTF Transfers: A Revolutionary Printing Method

Direct-to-Film (DTF) transfers have emerged as a revolutionary technique in the world of custom printing, enabling artists and crafters to produce stunning, high-quality images directly onto fabric. This innovative method involves a multi-step process where designs are printed on a special film, which is later transferred onto the material using heat and pressure. The versatility of DTF printing allows for applications on various substrates—ranging from cotton to polyester—making it ideal for both personal projects and commercial endeavors.

What sets DTF apart is its ability to create vibrant and durable prints that stand the test of time. Unlike traditional printing methods that may limit creativity based on fabric type, DTF transfers offer an expansive canvas of possibilities, allowing users to explore color and design without constraints. With the rapid advancements in technology, especially with platforms like Snuggle enhancing production capabilities, the DTF printing process is not just a trend but a cornerstone in the landscape of custom printing.

Why Choose DTF Transfers Over Traditional Methods?

In a comparative look at DTF and other printing methods, such as sublimation and screen printing, DTF transfers emerge as a favorable choice due to their versatility and cost-effectiveness. Sublimation, while excellent for polyester, fails to provide results on cotton, leaving many fabric options unexplored for those who prefer natural fibers. DTF technology, however, excels at transferring designs to a broader range of fabrics, opening up creative opportunities that were previously limited.

Furthermore, DTF transfers do not demand the same costly setup and bulk production requirements associated with screen printing. This makes DTF a smart alternative for small runs or one-off projects, where high-quality results are needed without the need for extensive initial investment. As such, crafting with DTF has become increasingly popular among DIY enthusiasts and small business owners looking to maximize their creativity without sacrificing efficiency.

The DTF Printing Process Demystified

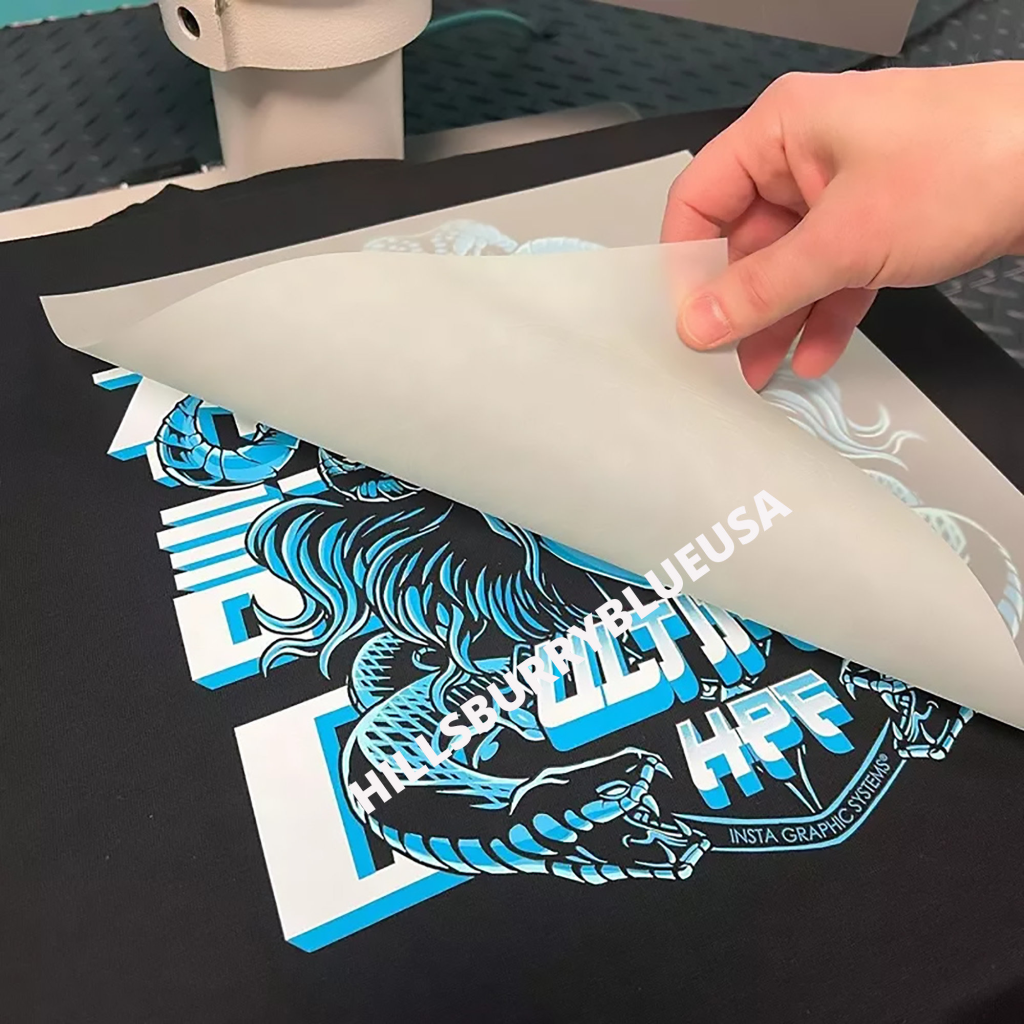

Understanding the DTF printing process is essential for anyone interested in harnessing this innovative technique. The journey begins with the creation of a digital design, which can be easily crafted using graphic design software or obtained from various online templates. Next, this design is printed onto specialized film using a DTF printer, which incorporates an adhesive layer—an integral step that ensures the longevity and vibrancy of the print once transferred.

Once printed, the film undergoes a curing phase where adhesive powder is applied and bonded through heat. Afterward, it’s ready for transfer—this involves placing the film onto the target fabric and applying heat with a heat press. The precise control of temperature and pressure during this process is critical to achieving an impeccable transfer, culminating in a durable and striking outcome. This multi-step procedure, though detailed, can lead to remarkable results and a fulfilling crafting experience.

DTF vs Sublimation: A Comparison for Crafters

When comparing DTF to sublimation, several critical factors come into play that can influence a crafter’s choice. Sublimation is a method that, while delivers vibrant colors on polyester, simply does not perform as effectively on cotton or other non-synthetic materials. This limitation restricts the textile options for crafters wishing to create diverse fabric products. In contrast, DTF printing shines with its compatibility with a range of materials, making it a more flexible solution for custom projects.

Crafters need to consider the practicality of each method. While sublimation requires specific fabric types for optimal results, DTF offers the luxury of selecting a wider variety of bases. This means less compromise on design choices, allowing creators to tailor their projects according to personal preferences and market demands. Thus, understanding DTF vs sublimation not only helps in selecting the right technique but also enhances overall creativity.

Key Applications for DTF Transfers: From T-Shirts to Promotional Items

DTF transfers have truly diversified the landscape of custom printing, showcasing their remarkable application across various products. Custom T-shirts stand out as one of the most popular uses for DTF, allowing individuals to express personal flair or commemorate events creatively. The vibrant colors and sharp details achieved through DTF printing ensure that each shirt not only looks great but lasts through multiple washes, maintaining its aesthetic over time.

In addition to apparel, DTF is making waves in the realm of promotional items. Businesses can benefit from this technology by branding merchandise that effectively showcases their identity. From tote bags to caps, the creativity unleashed via DTF transfers offers promotional items that truly resonate with their target audience. This versatility opens numerous avenues for entrepreneurs looking to make a statement through their merchandise.

Tips for Mastering DTF Printing: Best Practices for Quality Results

Embarking on your DTF printing journey requires a solid foundation of knowledge and preparation to achieve stunning results. One of the foremost tips is to invest in high-quality DTF printers and heat presses, as the durability and vibrancy of prints significantly rely on the equipment used. Selecting the right materials—inks, films, and powders—is equally essential, as they directly impact the final output quality and longevity of your prints.

Furthermore, conducting preliminary tests on similar fabric types can save time and resources. By experimenting with different designs and settings on sample fabrics, crafters can refine their approach, ensuring that the final product meets expectations. Adhering to these best practices will not only enhance your results but will also empower your creativity, making the DTF experience both enjoyable and rewarding.

Frequently Asked Questions

What are the benefits of using DTF transfers in custom printing?

DTF transfers offer multiple benefits in custom printing, including versatility for different fabrics, durability for long-lasting designs, and cost-effectiveness, especially for small batches. DTF is particularly advantageous because it allows for vibrant prints on various substrates, including cotton and blends, which traditional methods like sublimation cannot achieve.

How does the DTF printing process work?

The DTF printing process involves several steps: first, create or obtain a digital design. Next, this design is printed onto a special film using a DTF printer. After printing, adhesive powder is applied to the film and cured with heat. Finally, the film is pressed onto the fabric, transferring the design through heat and pressure, and peeled away to reveal the final product.

What is the difference between DTF and sublimation printing?

DTF and sublimation printing differ primarily in their material compatibility. Sublimation works best on polyester fabrics and may fade on cotton, whereas DTF transfers can be applied to a wide array of fabrics, including cotton and blends. This makes DTF a more versatile choice for custom projects.

Can DTF transfers be used for small custom projects?

Yes, one of the major advantages of DTF transfers is their suitability for small custom projects. DTF printing does not require the extensive setup costs associated with methods like screen printing, making it a cost-effective solution for individuals and small businesses looking to create unique designs without large batch commitments.

What types of items can I create with custom DTF transfers?

Custom DTF transfers can be used on a variety of items including custom t-shirts, hoodies, bags, hats, and other apparel and accessories. This technology allows for intricate, vibrant designs, making it an excellent choice for personalized gifts, branded merchandise, and promotional items.

What tips can help ensure successful crafting with DTF transfers?

To ensure successful crafting with DTF transfers, consider using quality equipment, such as a reputable DTF printer and heat press. Always select high-quality inks and films for better durability. Additionally, perform test prints on similar fabric types before finalizing your designs to avoid any unexpected issues or quality setbacks.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a film that is then transferred to fabric using heat and pressure. |

| Popularity Factors | DTF transfers are gaining popularity due to their versatility, durability, cost-effectiveness, and accessibility. |

| The DTF Process | The DTF transfer process includes design creation, film printing, adhesive application, transfer to fabric, and peeling. |

| Comparison with Other Methods | Unlike sublimation and screen printing, DTF offers flexibility and detail for both small and large projects. |

| Key Applications | DTF transfers can be used for custom T-shirts, hoodies, bags, promotional items and more. |

| Success Tips | Invest in quality equipment, use high-quality materials, and conduct tests for optimal results. |

Summary

DTF transfers offer a revolutionary way to enhance custom printing capabilities, allowing for creativity and versatility in design. As a modern solution in the printing landscape, DTF transfers enable users to create stunning prints on various fabrics with ease and efficiency. Whether used for personal projects or commercial applications, understanding the advantages and processes of DTF transfers can significantly improve the quality of your printing endeavors. By utilizing these techniques, crafters and businesses alike can tap into a world of vibrant aesthetics and endless possibilities.