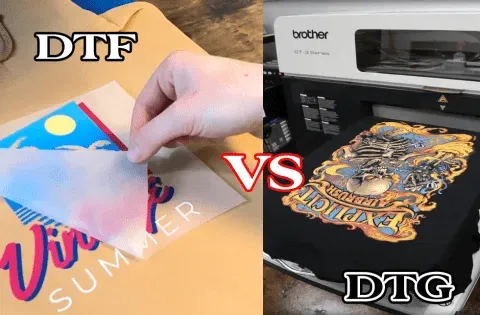

In the ever-evolving world of custom merchandise, the choice between DTF vs. DTG is a pivotal decision for businesses looking to optimize their apparel printing techniques. Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing methods each bring unique advantages to the table, making it crucial to compare their features. While DTG is renowned for its incredible detail and vibrant colors suitable for cotton fabrics, DTF impresses with its versatility across various materials and economical bulk production capabilities. As we delve into the differences between these popular printing methods, this comprehensive guide will help you understand the nuances of DTF vs. DTG printing, equipping your business with the knowledge to make informed decisions about custom merchandise printing. Let’s uncover the strengths of each method to determine which aligns best with your business needs.

When considering the printing options available for apparel, businesses often hear terms like film-printing technology or garment-printing techniques. Understanding these different terminologies—Direct-to-Film (DTF) and Direct-to-Garment (DTG)—can aid in navigating the vibrant landscape of custom merchandise production. DTF refers to a modern approach that transfers prints from a film to a variety of fabric types, whereas DTG leverages specialized inkjet technology for high-resolution prints directly onto garments. Exploring a printing methods comparison can reveal insights into which technique is more fitting for specific design requirements and production scales, ensuring that businesses meet their customers’ diverse preferences.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing is a modern method that has reshaped the landscape of custom merchandise production. This technique involves printing designs onto a special film that can be transferred onto various fabric types using heat. The ability to print on diverse materials such as cotton, polyester, and blends positions DTF as a versatile choice for businesses aiming to cater to a wide range of customer preferences. This adaptability plays a crucial role in today’s competitive apparel market, where customer demand for unique customization is at an all-time high.

DTF technology not only supports a variety of fabrics but also simplifies the setup process. The printing can be completed in-house, eliminating reliance on third-party suppliers for transfers. This leads to greater control over the production process and faster turnaround times, enhancing customer satisfaction. As an emerging player in the printing methods comparison arena, DTF offers unique advantages that appeal to startups and established businesses alike.

DTG Printing: A Closer Look at Its Benefits

Direct-to-Garment (DTG) printing is widely recognized for its ability to produce high-quality images with remarkable detail. This method is particularly effective for designs that require intricate details and rich color palettes. By directly applying the ink onto the fabric, DTG achieves a soft finish that integrates well with the garment, making it a favored choice for apparel printing techniques aimed at delivering comfort and style. For businesses focusing on high-end fashion or personalized merchandise, DTG can elevate their product offerings.

Additionally, DTG printing allows for easy customization without the burden of large minimum orders. Each piece can be printed as needed, which reduces waste and inventory costs for small businesses. This feature is especially beneficial for companies offering bespoke items or limited-edition collections. However, while DTG printing boasts notable advantages, its limitations with synthetic textiles might necessitate careful fabric selection to ensure optimal print quality.

Cost Considerations in DTF vs. DTG

When evaluating DTF versus DTG printing methods, cost plays a pivotal role in decision-making. DTF printing typically offers a lower cost per print, especially advantageous for bulk orders. The affordability of DTF setups allows businesses to maintain higher profit margins while meeting large-scale production demands. Companies that prioritize cost-effectiveness without compromising quality often find DTF to be the ideal solution, particularly in high-volume merchandise cases.

Conversely, DTG printers, despite their higher initial investment and ongoing costs, deliver unparalleled quality for complex designs and small batches. For small businesses that thrive on customization and value intricate details, the higher costs can be justified through enhanced customer satisfaction and loyalty. Once businesses weigh order volume and budget against their quality needs, they can make an informed decision on whether DTF or DTG is the right fit.

Target Market and Their Impact on Printing Choices

Understanding your target market is vital when choosing between DTF and DTG printing methods. For businesses catering to fashion-forward consumers who seek high-quality, personalized apparel, DTG is often the favored choice. The ability to achieve intricate designs with vibrant colors aligns perfectly with the expectations of consumers looking for unique, one-of-a-kind products. On the other hand, companies focused on providing cost-effective, high-volume merchandise may find greater success with DTF printing.

Moreover, the demographics of the customer base can influence printing choices as well. Younger audiences, who value personalization and eco-friendliness, might lean towards DTG prints for their softer feel and attention to detail. Meanwhile, businesses aiming at sportswear markets, where durability and fabric variety are key, may opt for DTF, given its compatibility with various synthetic materials. Overall, aligning printing methods with market demands ensures that businesses can maintain a competitive edge.

The Future of Printing Technologies: DTF and DTG

As technology advances, the landscape of custom merchandise printing continues to evolve, with both DTF and DTG methods experiencing enhancements. DTF is gaining recognition for its efficiency and ability to produce vibrant designs that can withstand the rigors of washing without fading. These advancements suggest that DTF may become increasingly popular among businesses seeking durability and versatility in their printing processes. Moreover, the ongoing research and development in printing technology are likely to introduce new materials and inks that further improve the capabilities of DTF printing.

DTG, too, is not without its innovations, as manufacturers work to refine the printing process and reduce costs. Developments such as faster printing speeds and improved inks are making DTG a more viable option for larger print runs, potentially closing the gap with DTF in terms of efficiency. By staying informed about trends in printing technologies, businesses can adapt to the changing landscape and choose the optimal printing method that supports growth and satisfies customer demands.

Final Thoughts on Choosing Between DTF and DTG

In conclusion, the decision between DTF and DTG printing methods hinges on various factors including product type, order volume, and budget. Businesses must carefully assess their needs and consider how each method aligns with their goals and customer preferences. DTF printing’s versatility and cost-effectiveness make it a strong contender for those focusing on bulk orders, while DTG’s detailed output and soft finish cater to a niche market that values quality over quantity.

Ultimately, by weighing the advantages and challenges of DTF versus DTG printing, businesses can make informed choices that enhance brand identity and customer satisfaction. Staying adaptable and engaged with market trends will empower companies to optimize their printing processes and fulfill the desires of their target audiences effectively.

Frequently Asked Questions

What are the main differences between DTF vs. DTG printing?

DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing differ in several key aspects. DTF prints designs onto a special film, allowing transfers to various fabrics, while DTG sprays ink directly onto fabric, ideal for detailed prints on cotton. DTF offers more versatility and cost-effectiveness for bulk orders, whereas DTG excels in detail and quality for smaller, custom runs.

Is DTF printing or DTG printing better for intricate designs?

For intricate designs, DTG printing is generally the better option due to its ability to produce high detail and vibrant colors directly on the fabric. It handles fine lines and gradients exceptionally well compared to DTF, which may not capture the same level of detail in complex artworks.

Which printing method, DTF vs. DTG, is more cost-effective for bulk orders?

DTF printing tends to be more cost-effective for bulk orders. It typically has a lower cost per print, making it a suitable choice for businesses that need to produce larger quantities without compromising quality, in contrast to DTG, which can be more expensive for high-volume production.

Can DTF vs. DTG printing be used on all fabric types?

No, DTF and DTG printing have different fabric compatibility. DTG printing works best on 100% cotton fabrics, while DTF printing can be used on a wider range, including polyester and cotton blends. If your business ventures into various fabric options, DTF provides greater versatility.

What are the durability differences between DTF and DTG prints?

DTF prints are known for their durability and can withstand numerous washes while maintaining vibrancy, making them ideal for long-lasting merchandise. DTG prints, while high-quality, may fade faster if not properly cared for, especially on non-cotton fabrics.

How do initial equipment costs compare for DTF vs. DTG printing?

Initial equipment costs for DTG printing are usually higher due to the specialized printers needed and the pretreatment process required. In contrast, DTF printing setups can be more affordable, making them more accessible for businesses starting in custom merchandise printing.

| Key Factors | DTG (Direct-to-Garment) | DTF (Direct-to-Film) |

|---|---|---|

| Overview | Ink is sprayed directly onto fabric, ideal for detailed designs. | Designs are printed on film, then transferred to fabric; versatile for different materials. |

| Advantages | High detail, soft finish, easier customization. | Versatile fabric compatibility, cost-effective for bulk, durable prints. |

| Disadvantages | Limited fabric compatibility, higher equipment costs. | Thicker feel on fabric, less detail for intricate designs. |

| Best For | Personalized and high-quality items for smaller orders. | Mass-market products, especially in larger runs. |

Summary

DTF vs. DTG printing methods are pivotal decisions for businesses involved in custom merchandise. Each option offers distinct benefits and challenges that cater to varying needs. DTG provides superior detail and softness, making it ideal for intricate, high-quality garments, while DTF’s versatility and cost-effectiveness shine in bulk production scenarios. Understanding these differences allows businesses to align their printing choice with customer demands and operational goals effectively. Ultimately, choosing between DTF and DTG should consider factors like design complexity, order volume, and fabric types to ensure maximum satisfaction and business growth.