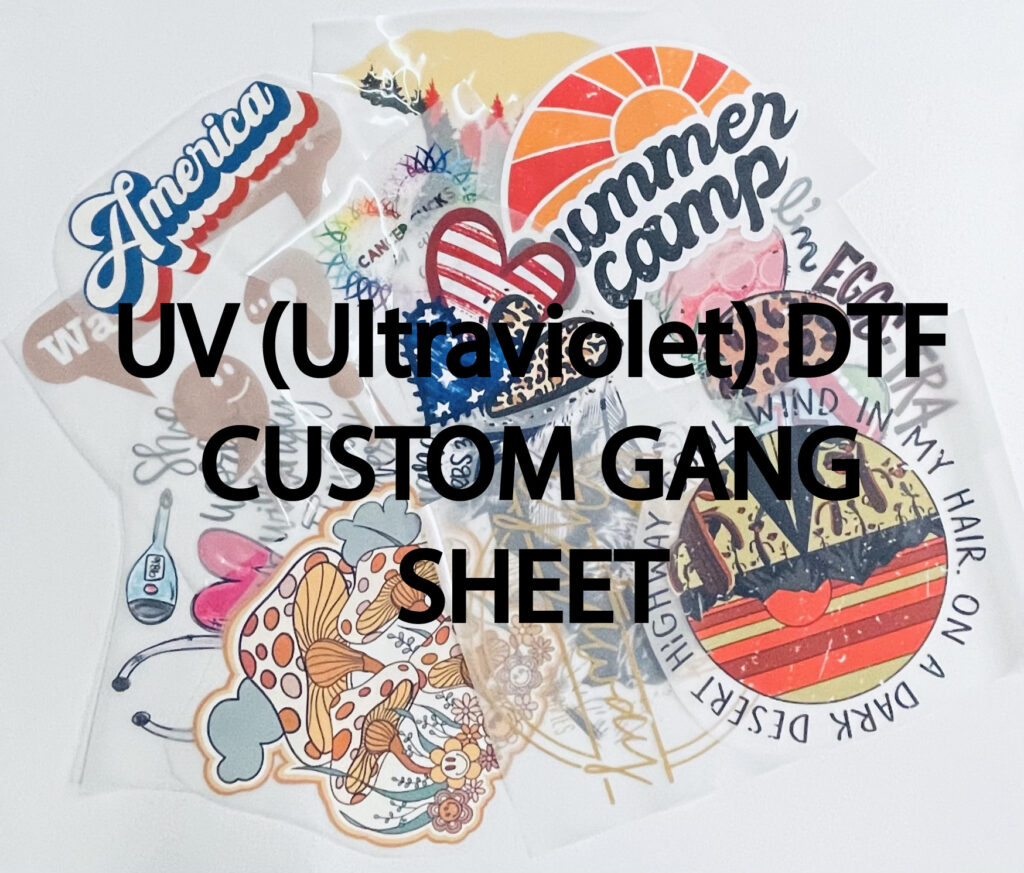

In the realm of contemporary printing solutions, **UV DTF Gang Sheets** have emerged as a groundbreaking method that synergizes UV printing technology with Direct-to-Film (DTF) techniques. This innovative approach allows for the simultaneous printing of multiple designs on a single sheet, greatly enhancing efficiency while minimizing material waste. By strategically leveraging DTF printing, businesses can achieve high-quality, vibrant printed designs that stand out in a competitive marketplace. Moreover, the use of gang sheets not only cuts overall production costs but also streamlines the workflow, making it an ideal choice for custom printing solutions. In this article, we will explore the intricacies of UV DTF gang sheets and their transformative impact on the printing industry.

In today’s fast-paced printing industry, the concept of gang sheets is revolutionizing how custom designs are produced. Essentially, DTF (Direct-to-Film) gang sheets streamline the process of applying multiple printed graphics in one pass, optimizing time and resources. By incorporating UV printing technology, this method enhances durability and vibrancy in printed outputs. These custom printing solutions offer artists and businesses the flexibility to create a diverse range of products that meet the demands of modern consumers. With the rise in popularity of UV DTF gang sheets, understanding this advanced technique is essential for anyone looking to make their mark in the crowded design landscape.

Understanding DTF Gang Sheets in Modern Printing

DTF gang sheets represent a crucial innovation in the landscape of printing technology, specifically designed to enhance efficiency and reduce costs. The essence of these gang sheets lies in their ability to consolidate multiple designs onto a single sheet, which can significantly lower printing expenses, especially for small to medium-sized businesses. By optimizing how prints are arranged, DTF gang sheets make it possible for companies to execute smaller runs without sacrificing quality or incurring hefty expenses.

In addition to cost savings, DTF gang sheets also contribute to a more sustainable printing process. By minimizing material waste, they align with the increasing market demand for eco-friendly practices. Whether it’s for custom apparel, promotional items, or home decor, utilizing gang sheets ensures that businesses can meet diverse customer needs while also committing to environmental responsibility.

Innovations in UV DTF Printing Technology

The evolution of UV DTF printing technology showcases the rapid advancements within the industry, marking a shift towards greater versatility and quality. UV printing, characterized by its ability to cure inks instantly using ultraviolet light, when combined with DTF technology, enables the creation of vibrant, detailed designs that last longer. This intersection of technologies harnesses the strengths of UV inks, which offer superior adhesion and resistance to colors fading over time.

Recent developments in UV DTF printers, like those produced by Anker, reflect this technological leap, allowing for intricate and varied applications on diverse materials such as textiles and plastics. This not only encourages artistic freedom for designers but also provides manufacturers with a robust tool for producing durable prints across an expanded product range.

The Creative Process Behind UV DTF Gang Sheets

Creating effective UV DTF gang sheets begins with a meticulous design integration process. Graphic designers utilize specialized software to compile multiple designs on a single digital template. Using tools such as Adobe Illustrator and CorelDRAW allows them to strategically arrange the artwork, ensuring that every inch of the gang sheet is used efficiently for printing. The creative aspect of this process is vital, as it determines the overall aesthetics and layout of the final printed product.

Once the designs are arranged, the printing process employs direct-to-film technology to transfer the images onto specially coated film. The application of vibrant inks during this stage will not only enhance the color vibrancy but will also promote adherence, setting the foundation for high-quality prints. Through careful attention to both design and printing techniques, businesses can ensure the final output is not just visually appealing but also durable and long-lasting.

Unique Benefits of UV DTF Gang Sheets

One of the standout advantages of using UV DTF gang sheets is their cost efficiency. By consolidating multiple designs, businesses can significantly reduce printing costs, making it an appealing solution for startups and small enterprises. This economical approach not only helps save money but also ensures that resources are utilized optimally. Thus, companies can allocate more funds toward other important areas such as marketing and expansion.

Additionally, the use of UV DTF gang sheets plays a critical role in minimizing waste, aligning with eco-conscious initiatives that are gaining momentum in today’s market. By maximizing the use of every inch of printable material, these gang sheets contribute positively to sustainability, meeting the growing consumer expectation for environmentally friendly practices. Brands that adopt these methods not only save costs but also enhance their reputation as responsible manufacturers.

Emerging Trends in the UV DTF Printing Market

The demand for UV DTF gang sheets is witnessing a significant surge, primarily driven by the rising consumer appetite for customized products. As businesses, especially in the retail segment, seek ways to differentiate themselves in a saturated market, the ability to offer personalized prints at competitive prices is becoming increasingly essential. This trend is bolstered by advancements in DTF technologies that enhance printing capabilities and efficiency.

Furthermore, the emergence of smaller, personal 3D texturing UV printers is enabling freelancers and small businesses to enter the market with minimal investment. This democratization of technology allows a broader range of players to offer high-quality printed designs, impacting the future of printing services by fostering innovation and creativity across different sectors.

Conclusion: The Future of UV DTF Gang Sheets

The exploration of UV DTF gang sheets reflects not only advancements in printing technology but also the ongoing evolution of consumer expectations. As businesses integrate these innovative printing solutions, they are not only improving their operational efficiency but also tapping into a vibrant market for unique and customized designs. The combination of cost-effectiveness, reduced waste, and the ability to produce eye-catching prints positions UV DTF printing as a crucial element in the future of custom printing solutions.

As we look ahead, businesses that leverage these technologies will likely find new avenues for growth and creativity in an ever-evolving marketplace. The art of UV DTF gang sheets is more than just about printing; it’s about forging a path toward sustainable and adaptable business practices that prioritize both quality and responsibility.

Frequently Asked Questions

What are UV DTF Gang Sheets and how do they enhance printing efficiency?

UV DTF Gang Sheets are a modern printing solution that combines UV printing technology with DTF (Direct-to-Film) methods. They allow multiple designs to be printed on a single sheet, optimizing the printing process and minimizing material waste. This efficiency is particularly beneficial for businesses, as it reduces production costs and time associated with setup.

How do DTF Gang Sheets differ from traditional printing methods?

DTF Gang Sheets differ from traditional printing by enabling the simultaneous printing of several designs on one sheet, thereby maximizing resource use and minimizing waste. In contrast, traditional methods often require individual prints for every design, leading to higher costs and longer turnaround times.

What are the key steps in creating UV DTF Gang Sheets?

Creating UV DTF Gang Sheets involves three key steps: 1) Design Integration, where multiple designs are arranged optimally using graphic design software; 2) the Printing Process, where these designs are transferred onto a specially coated film with vibrant inks; and 3) Curing and Application, where the printed film is cured with UV light before transferring the designs onto various substrates.

What advantages do UV DTF Gang Sheets offer for small businesses?

UV DTF Gang Sheets provide several advantages for small businesses, including cost efficiency by reducing printing expenses, minimized waste contributing to eco-friendliness, and versatility in design that allows for a broader range of custom printing solutions. These benefits make it easier for small businesses to compete in the personalized product market.

How does UV printing enhance the quality of designs on DTF gang sheets?

UV printing enhances the quality of designs on DTF gang sheets by using vibrant inks that produce rich colors and sharp details. Additionally, the curing process solidifies the inks, resulting in durable prints that can withstand fading and wear, providing long-lasting results compared to conventional methods.

What market trends are influencing the demand for UV DTF Gang Sheets?

The demand for UV DTF Gang Sheets is influenced by trends favoring customized prints at competitive prices. Innovations in printing technology, particularly from companies like EazyDTF, have increased the capacity for large-format printing jobs, enabling quick turnaround times. Additionally, the rise of affordable personal UV DTF printers allows small businesses to enter the market with lower initial investments.

| Key Point | Description |

|---|---|

| Introduction to UV DTF Gang Sheets | Combines UV printing and DTF methods for efficient design production. |

| What are DTF Gang Sheets? | Sheets that optimize printing by allowing multiple designs to be printed at once, reducing costs and waste. |

| The Evolution of UV DTF Printing Technology | Recent advancements are enhancing the adaptability and quality of prints across various surfaces. |

| The Art of Creating UV DTF Gang Sheets | Involves design integration, printing process, and curing/application of prints. |

| Advantages of UV DTF Gang Sheets | Cost efficiency, minimized waste, and versatile design capabilities make gang sheets appealing. |

| Current Market Trends | Growing demand for customized prints with innovations improving accessibility and efficiency. |

Summary

UV DTF Gang Sheets represent a significant advancement in printing technology, combining the efficiency of DTF with the vibrancy of UV printing. This modern approach not only enhances production capabilities but also addresses the demand for sustainability by minimizing waste. As businesses increasingly adopt this technique, the future of printing appears bright, promising higher quality outputs and a broader range of customizable products that cater to diverse market needs.